Anti-Vibration Pads vs. Spring Pads: Which is the Best Choice for High-RPM Blowers in India?

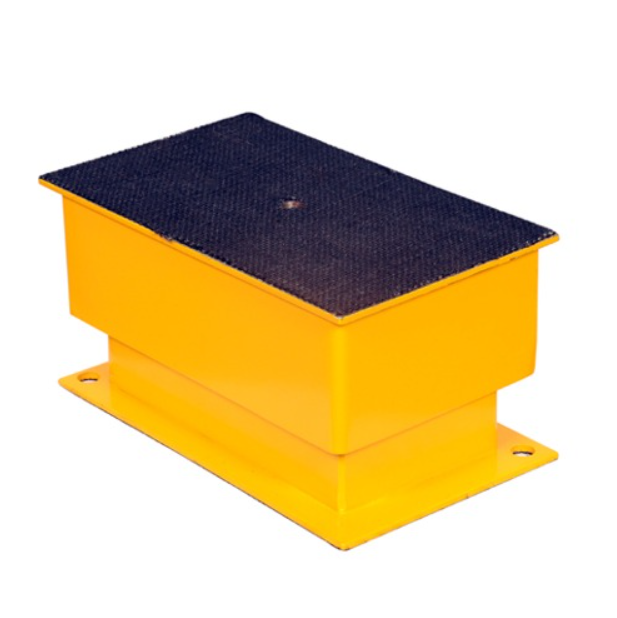

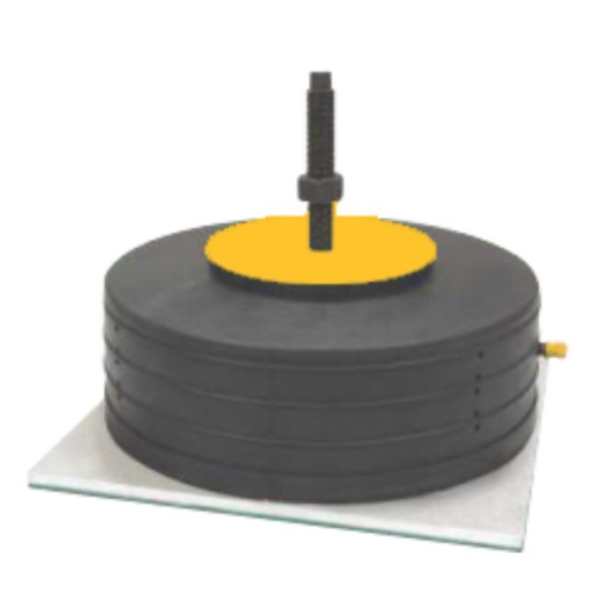

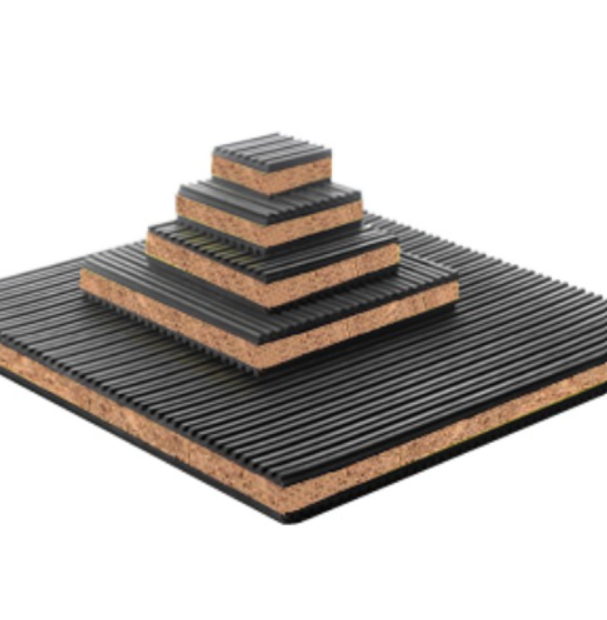

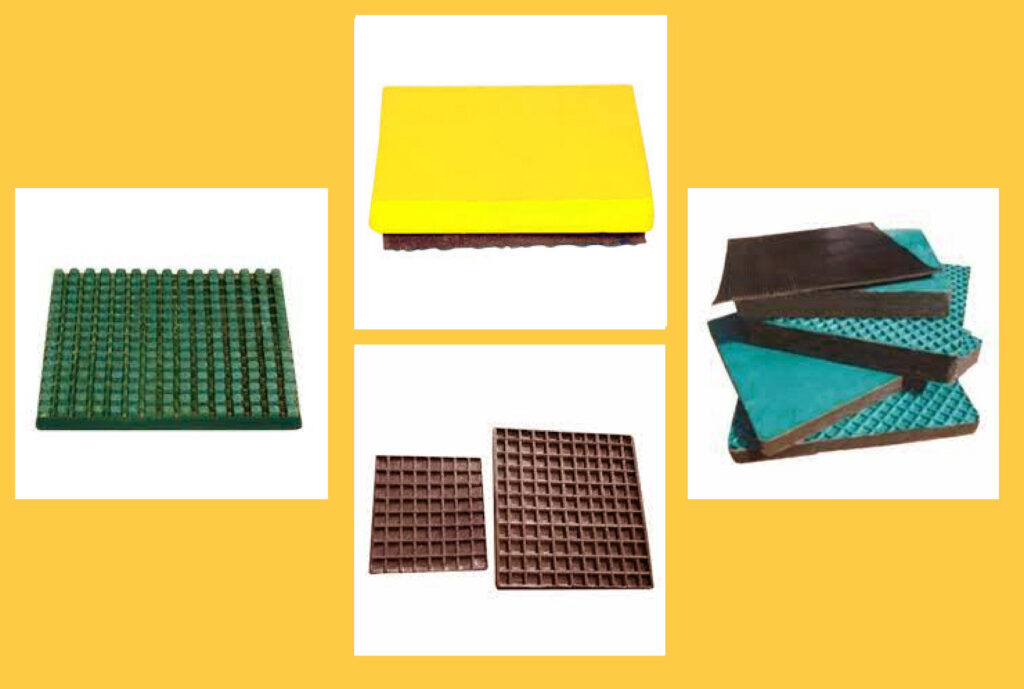

High-RPM blowers are a must-have in different industrial applications like HVAC systems and processes that involve manufacturing. But the problem of vibration, if it becomes excessive, can slash their life expectancy drastically, besides causing higher maintenance costs and lower efficiency of operations. Hence, picking the right vibration isolation solution is of utmost importance. In India, there are two main contenders in the market: Anti-Vibration Pads and Spring Pads. This article gives a glimpse of their characteristics, advantages, and usage henceforth to guide the industries in making the right choice. Understanding the Role of Vibration Control in High-RPM Blowers Vibration control is not merely an issue of comfort; it has a direct impact on the performance, reliability, and safety of industrial equipment. High-RPM blowers develop oscillations that may: Hence, the use of proper vibration isolation solutions is an assurance that the machinery runs without problems, there are no unplanned shutdowns, and the equipment life is prolonged. Plus, it cuts down on maintenance costs which is especially important in large industrial setups where the demand for the product is continuous. Anti-Vibration Pads: Durable and Cost-Effective Performance Solutions Anti-vibration pads consist of very elastic materials like rubber, neoprene, or composite polymers. Their function is to absorb the shocks and not allow the vibrations of the machinery to reach the surrounding structures. The main features of Anti-Vibration Pads: Advantages of Anti-Vibration Pads: Among other things, it is the case that anti-vibration pads work particularly well in situations where the area is small or where the equipment is of moderate weight. Spring Pads for Precision and Stability in Industrial Applications Spring pads, also referred to as coil spring isolators, are mechanical vibration absorbers that consist of steel springs and damping materials. They are designed for precision and industrial use in very demanding environments. Main Characteristics of Spring Pads: Advantages in Industrial Applications: Therefore, spring pads are the equipment of choice when high-performance and reliability cannot be compromised. Comparing Key Parameters: Load Capacity, Maintenance, and Longevity When making the choice between anti-vibration pads and spring pads, the industry should weigh the following parameters: 1. Load Capacity: 2. Maintenance Requirements: 3. Longevity: 4. Noise Reduction: Therefore, the final decision comes down to operational requirements, load restrictions, and budget limitations. Why Unick Vibration Leads India’s Market in Blower Isolation Solutions Unick Vibration is the king in the anti-vibration and spring pad market in India. Plus, the company’s products stand out in industrial applications as they combine durability, accuracy, and reliability. Reasons for Unick Vibration’s Dominance in the Market: Besides this, Unick Vibration’s innovations are geared towards less maintenance time, better efficiency, and safeguarding of the infrastructure—making it a reliable partner for industries all over India. Conclusion The choice between using anti-vibration pads and spring pads for high RPM blowers in India calls for a thorough analysis of load capacity, maintenance needs, and operational requirements. It is the right solution that eventually brings about the long-term reliability of the equipment, lower maintenance costs, and safer working conditions. Thus, before making a decision, industrial operators should assess their particular needs carefully. Protect Your High-RPM Blowers Today! Unick Vibration is the one-stop shop for vibration and spring pads with superior performance and long life. Please do not hesitate to get in touch with us by phone at +91- 9718575974 or by going to the website of Unick Vibration and requesting a consultation so that your blower’s efficiency can be optimized.

Top 5 Reasons Unick Vibration is the Best Spring Pad Manufacturer for Bending Machines in India

Selecting the correct spring pad is critical for bending machines’ performance and longevity to the fullest. Unick Vibration, a top spring pad maker in India, has established a fantastic reputation for providing quality, long-lasting, and high-precision spring pads. In the following article, we will look at the five main reasons that make Unick Vibration the favoured choice for various industries in India. Precision Engineering That Enhances Bending Machine Performance Unick Vibration is all about making spring pads that are precisely and painstakingly designed to give to the bending machines the power and accuracy they need to be perfect. Moreover, these high-precision pads not only boost the performance of the machine but also save on maintenance costs throughout the period. Thus, manufacturers will have higher productivity and good quality output consistently. High-Quality Materials Ensuring Long-Lasting Durability The industrial equipment’s durability is always a major concern. Unick Vibration utilizes the finest materials to keep their spring pads that can suffer the most severe conditions and hold up to maximum usage. On top of that, the selection of high-grade materials leads to the anti-vibration pads service life being extended and consequently fewer replacements being done. Furthermore, such longevity assures the steady machine operation, which is very crucial for industries that have strict production timelines. Unick Vibration’s Expertise in Custom Spring Pad Solutions The most important reason why Indian industries prefer Unick Vibration the most is that they can offer custom-made solutions that are designed specifically for them. Thus, the customers are provided with spring pads that are exactly in accordance with the specifications of their bending machines, which leads to the attainment of maximum efficiency and the least downtime. As a result, this custom method gives Unick Vibration a competitive edge over non-specialized manufacturers. Rigorous Quality Testing for Superior Vibration Control Unick Vibration implements very rigorous quality control policies and practices so as to make sure that every spring pad offers exceptional vibration reduction and stability in operating performance. Besides, the rigorous quality controls allow for the flawless operation of each spring pad even under the toughest working conditions. So, bending manufacturers can take the guarantee of Unick Vibration pads for the stability and efficiency of their operations. Trusted by Leading Industries Across India for Consistent Results The large-scale reliance of major Indian industries on Unick Vibration products is an indication of the quality and consistency of performance on the part of the manufacturer. Thus, firms that especially value quality, longevity, and performance always resort to Unick Vibration. Besides, their commitment to the customer flourishes through increased operational efficiency and lesser chances of machine failure due to unforeseen circumstances. Conclusion To sum up, Unick Vibration becomes the best spring pad manufacturer for bending machines in India by offering: By choosing Unick Vibration, manufacturers not only invest in the best spring pads but also reap improved machine efficiency, less downtime, and increased productivity. Make a Move Now! Give your bending machine new life with Unick Vibration’s top-notch spring pads. Get in touch with us right away to find out about personalized solutions that meet your demands and to enjoy unmatchable durability and precision. Feel the Unick Vibration difference – where precision blends with durability.

The Ultimate Fix for Machine Vibration: Why Unick Levelling Pads are India’s #1 Choice

Industries machines form the backbone of workshops in manufacturing, production, and engineering. Machine vibrations stand as a constant challenge lowering efficiency and working against the machine’s life. Vibration in own turn is just noise; it is a silent drain on industries. And, hence, go to Unick Levelling Pads for the solution. And even further, it stands as the No.1 choice for vibration control in India. With reliability conferred upon them, forefront design, and maximum durability, Unick Vibration Solutions is about to change the approach of machinery stability in industries. Understanding the Root Causes of Machine Vibration in Industrial Setups Every industry faces vibration problems at some point, and it is very important for the proverbial crux of the issue to be understood before a solution is applied. In addition, vibrations of machines come due to many interrelated reasons, which in turn means ignoring vibrations leads to damage in the long haul. Vibration issues may arise due to: Hence, it is very important to diagnose vibrations at the root. Application of right solution thereafter guarantees smooth and safe operations. How Unick Vibration Solutions Ensure Maximum Stability and Performance Unick Vibration expert has spent decades in developing vibration control solutions. Firstly, unlike normal vibration damper Unick Levelling Pad is specially designed. And it is important to have the things that may not be compromised on performance, stability, and safety in the industrial fields. Key features that guarantee performance: Therefore, Unick Pads become a massive foundation of stability. And, at the same time, they enhance machine productivity while cutting down the operating cost. Top Benefits of Using Unick Levelling Pads for Heavy Machinery Unick Levelling Pads used by industries offer a myriad of benefits besides vibration control. They offer safety in the long term as well. Some major benefits include: That makes it an instant benefit. And with time, they add up to long-term profits for the industries. Why Industries Across India Trust Unick for Vibration Control When it comes to the machinery of industrial application, proven performance becomes the basis of trust. Unick has always stood for reliability. In the meantime, industries across India have begun trusting their solutions. Reasons that lead to this trust include: So in the course of solving vibration problems, Unick has built a network of permanent partner companies across many sectors. Choosing the Right Levelling Pad: A Step Towards Longer Machine Life No two levelling pads are alike. It is incumbent upon the purchaser that the right one is selected for ensuring optimal performance of a machine. Accordingly, Unick provides an exhaustive range of Heavy Duty Anti Vibration Pads for levelling pads to meet the needs of multiple industries. And so, the machines gain stability like never before. Steps to choosing the right levelling pad: Thus, choosing the right levelling pad will not just minimize vibrations but also further increase the life of the equipment and lessen maintenance cycles. Conclusion Vibration in a machine is all in all an inconvenience and is a hidden threat to industrial production, safety, and profitability. Yet, the solution is simple. And there lies Unick Levelling Pads-the most trusted number one manufacturer of levelling pads in India. From improving machine life to operational efficiency, these pads provide industries throughout the country with unbeatable value. Simply put, Unick is not just a product provider. The company provides industries an assurance of no downtime. Ready to eliminate machine vibration once and for all? So go by Unick Levelling Pads for that-ever-lasting exponential difference in performance, stability, and machine life.

The Role of High-Quality Insulation Sheets in Preventive Maintenance

In the present industrial context, time is everything to guarantee preventive maintenance, prerequisite for the operations to run smoothly, reducing downtime and enhancing the life of the equipment. Among the many tools and materials available to attain this level of functionality, high-quality insulation sheets have come to take one of the topmost positions. In fact, insulation sheets help protect the machinery themselves, optimize energy usage, and guarantee worker safety. Further, they save the industry from high repair charges and ensure greater reliability for Vibration control system. Why Insulation Sheets Are Essential for Preventive Maintenance in Industrial Settings Preventive maintenance is prognosis. Therefore, industries do not wait for machinery to fail; instead, they anticipate possible problems and resolve them prior to exacerbation. This is where insulation sheets become very useful. The integration into preventive maintenance schedules allows industries to upgrade efficiency greatly while reducing operational risks. Enhancing Equipment Longevity: How High-Quality Insulation Prevents Unexpected Failures Equipment failure stands expensive and disruptive to the extent that high-quality insulation sheets serve as the first line of defense against such detriments before they could befall the medium. In reality, laden industries with high-class insulation sheets record fewer unexpected breakdowns and stand to gain increased equipment life cycles. Energy Efficiency and Safety Benefits of Premium Insulation Sheets The premium insulation sheets confer the highest benefits in energy optimization and improved safety. So, insulation sheets contribute to saving on material costs, provide environment-friendliness, and promote workplace safety. Unick Vibration’s Trusted Solutions: Reliable Insulation Sheets for Preventive Maintenance A trusted partner means everything when it comes to preventive maintenance. One of the leading names for Insulation Sheets Manufacturer in India for industrial solutions, Unick Vibration supplies quality, dependable insulation sheets designed to cater to the modern industrial demand. Well, by having Unick Vibration as their partner, companies ensure preventive maintenance with the highest standards of excellence and innovation. Key Factors to Consider When Choosing the Right Insulation Sheets Choosing the right insulation sheet needs to be a well-thought-out decision. Hence, businesses must evaluate the following factors: Further considering these factors will ensure that the selected insulation sheets will be an asset both immediately and long term in preventive maintenance programs. Conclusion Preventive maintenance, unfortunately, is not given an option but rather an imperative for industrial success. Quality insulation sheets support machinery, Energy efficiency improvement measures are also put in place in the plants, along with provisions for worker safety. Moreover, these measures help equipment with longer life and less downtime, resulting in reduced costs. Hence, what you pay for today in insulation sheets is the investment into the productivity of tomorrow. Unick Vibration, therefore, has taken a lead in delivering first-rate insulation that industries can rely on. And thus, any company that values insulation and wants its operational excellence and long-term growth will have insulation provided by Unick Vibration. Want to rightly back your preventive maintenance with quality insulation sheets? Call Unick Vibration at +91 9718575974 and visit our website for solutions the industry can rely on: dependable, durable, and energy-efficient

What Are Heighten Mounts? A Beginners Guide by Unick Vibration Expert

Vibrations, in the realm of heavy-duty machinery, range from being an irritant to a serious problem affecting performance, safety, and the longevity of equipment. This is where Heighten Mounts enter into the picture. Designed to contain and limit vibration, such mounts offer companies a way to shield their equipment and maintain smooth operations. For a layperson in the initial stages of learning about heavy duty anti vibration pads solutions, understanding how these Heighten Mounts serve their purpose and why they are required becomes a crucial first step. In this guide put out by Unick Vibration Expert, we will take you through the fundamentals, benefits, and finally how to select the right solution for your machine. Understanding the Basics: What Exactly Are Heighten Mounts? In other words, Heighten Mounts combine the benefits of vibration isolation and machine leveling in one compact solution. Key Functions of Heighten Mounts: How Do Heighten Mounts Improve Vibration Control in Machinery? Machines vibrating at high speed or under heavy loads generate vibrations, which if unchecked, develop into: Here’s how they are at work in their maintenance: As a result, application offers a smoother performance, sound comforts, and reduced downtime. Key Benefits of Using Heighten Mounts in Industrial Applications Heighten Mounts are utilized in every industry from manufacturing to power plants. Besides vibration control, the applications of these mounts may gain in cost effectiveness. Major Advantages: On top of that, Heighten Mounts help to ensure adherence to workplace safety standards by maintaining equipment stability and reducing hazards. Why Choose Unick Vibration for Reliable Heighten Mount Solutions? Not all vibration controls are of the same nature. Unick Vibration stands apart for its quality, innovation, and customer-oriented approach as the best Heighten Mounts Manufacturer in India. Here are some of the reasons why industries rely on Unick Vibration: Hence, customers get offered solutions that are efficient and long lasting. Beginner-Friendly Tips for Selecting the Right Heighten Mounts Purchasing the correct mount can be a major decision for a beginner. However, if one keeps certain practical points in mind, the whole journey gets simpler. Easy Step-by-step guide to choosing Heighten Mounts: By the above-mentioned beginner-friendly tips, you will be able to make a good choice that will not let you down in the future. Conclusion Heighten Mounts are much more than industrial accessories: these work as essential components that protect machinery from vibration and extend life. For a beginner trying to set up some sort of vibration control for a machine, the first step is grasping the basic concepts, benefits, and selections. On the last note, buying trustworthy products from a brand you can trust, such as Unick Vibration, will guarantee your equipment functions smoothly and efficiently, not to mention safely. Ready to take the very first step into better vibration control? Be it your machinery installation or renewal of your existing installations, Unick Vibration has the answer through its Heighten Mounts. Contact Unick Vibration Expert today to find the right mount for your machinery. Call us right now or check out our website for more information on our solutions. Don’t wait any further. Prolong your machinery and improve efficiency and status quo with Unick Vibration Heighten Mounts

How to Install and Maintain Stud Mounts for Maximum Lifespan and Performance

Stud mounts act as shock absorbers preventing a machine from vibration, noise, and stress. They are widely used in manufacturing with automotive and heavy machinery. Having the ability to absorb and isolate vibrations leads to increased operational efficiency and longer life for machines; however, their proper installation, maintenance, and examination are extremely important to truly benefit from such mountings. A study on installation, maintenance, testing procedures, and performance enhancement methods will be presented here with heavy duty anti vibration pads. Several important ideas will aid any facility manager, engineer, or technician to keep their stud mounts at maximum efficiency and further operations towards ultimate life. Step-by-Step Guide: Proper Installation Techniques for Stud Mounts Correct Installations and Mounting are important to prevent mechanisms from vibration and premature wear. Below is the stepwise professional and easy-to-follow installation procedure. 1. Preparation and Surface Inspection 2. Positioning the Stud Mount 3. Tightening the Studs 4. Vibration Testing After Installation Pro Tip: Always record the installation specifics, including date, torque, part numbers, for possible future reference. Common Mistakes to Avoid During Stud Mount Setup Even a highly experienced technician may sometimes err in a way that shortens the lifespan of a stud mount. Avoiding these mistakes will save one both time and money. By avoiding such pitfalls, your stud mounts will work efficiently and safely for a longer period. Unick Vibration’ Recommended Practices for Stud Mount Maintenance The name of the leading Stud Mounts Supplier in India, Unick Vibration, whose mounts are best for systematic and routine maintenance to ensure the highest level of performance, is here. These are as follows: their best practices. How Regular Inspections Improve Stud Mount Lifespan and Safety Inspections ought to be performed routinely so as to identify faults before serious downtime or damage occurs to the equipment. A well-defined inspection program even greatly contributes to the expansion of stud mounts life. Inspection Checklist: Benefits of Regular Inspections: Performance Tips: Maximizing Efficiency and Durability of Stud Mounts While working for best results using stud mounts, a professional must be concerned not only with installation but also with performance enhancement in the long-term. Best Practices to Maximize Performance: Stud mount users with preventive maintenance programs reported 25-to-30 percent longer mount life than those facilities that only replaced them after failure. Conclusion The stud mounts seem to be small components, but they greatly affect machine stability, operator comfort, and longevity of other equipment. If the mounts are put in with the correct steps, avoid common mistakes, and follow industry-recommended maintenance procedures, the life of the mounts can be enhanced greatly. It may require periodic inspection and preventive maintenance to keep the equipment in good shape, thus minimizing downtime, saving cost of repair, and enhancing safety in the work environment. A very small effort in mounting and maintenance will go a long way in ensuring the stud mount lives up to its fullest potential. Want to increase your machinery’s performance and life with good-quality stud mounts? Unick Vibration is a premiere name in vibration control. From installation know-how to maintenance products, we have you covered so that your equipment will run smoothly, safely, and longer. Contact Unick Vibration today to discover the best stud mount solutions for your industry needs

What Are Levelling Pads? A Complete Guide for Indian Factory Owners

In the Indian manufacturing sector, machinery performance and workplace efficiency are the basis for any growth. Even a slight imbalance in a piece of equipment can lead to vibration, noise, or misalignment, each leading to a fall in productivity and increase in maintenance. And this is where levelling pads come in handy for Vibration control system solution. With their simplest definition, these pads keep the machinery steady, balanced, and efficient. For any Indian factory owner who wants to reduce downtime and improve operational flow, levelling pads are not just accessories but smart investments. Understanding Levelling Pads: Definition and Purpose in Indian Factories Levelling pads, also called machine mounts or anti-vibration pads, are industrial supports placed beneath machinery to maintain balance and minimize vibration. In Indian factories wherein the production lines are largely in continuous until time, levelling pads become essential for extending machinery life and ensuring constant product quality. Thus, they are said to protect while simultaneously boosting performance. Types of Levelling Pads Commonly Used in Industrial Setups Levelling pads are of different types based on varying needs across industries with respect to the weight of the machinery, vibration levels, and condition of the floor. Some common ones are: 1. Adjustable Levelling Pads 2. Anti-Vibration Pads 3. Fixed Levelling Pads 4. Hygienic Levelling Pads Choosing the correct one requires factory owners to basically carefully evaluate the needs of their machines. Key Benefits of Installing Levelling Pads in Your Factory Levelling pads serve more than just a balancing function and are directly responsible for machine efficiency, safety, and quality of production. Some of the major advantages include: With these considerations, levelling pads turn into a solution to protect machines as well as the floors. Why Indian Manufacturers Trust Unick Vibration for High-Quality Levelling Pads When it comes to Levelling Pads Supplier India, quality is as much a concern as functionality. Most Indian manufacturers try and believe Unick Vibration to be the leading innovator with durable solutions in vibration control. Highlights of Unick Vibration levelling pads: Also, Unick Vibration products go through rigorous testing to perform reliably even under the most adverse conditions in the factory. Buying Guide: How to Choose the Right Levelling Pads for Your Machinery In buying levelling pads, besides the price, one must consider several other factors before choosing the right levelling pad for his factory premises. Factors to Consider Before Buying: Brand Reliability: Always choose brands that have proved their quality over time and Unick Vibration is one. Pro Tip: Do not compromise on quality for a cheap price. Maintenance cost saved by a properly-selected levelling pad is many times more than the cost of the pad. Hence, an investment well made today would ensure smooth operation tomorrow. Conclusion Levelling pads may seem like minor fittings, but their impact on Indian factories is fiercesome and long-lasting. Maintenance of machine balance against vibrations, as well as productivity, is considered by them. Not Indian manufacturers, but that is out of the question for their respective competitors considering imbalances create inefficiency. Hence the reason Unick Vibration, being a brand of good repute, is the ideal choice when it comes to levelling pads. Through a judicious approach in considering the kind of levelling pad, factory owners reap efficiency, cost reductions, and smooth-running production lines. Are your machines running to their optimum? Do not let imbalance reduce your productivity! Unick Vibration premium levelling pads are what your factory deserves! Contact us for a custom levelling pad solution to fit your machinery.

Anti Vibration Rubber Pad at Best Price in Haryana

If you are looking for high-quality anti-vibration rubber pads at an affordable price, you’ve come to the right place. Our company offers a wide range of anti-vibration rubber pads that are designed to reduce noise and vibration in various applications. We are a leading and highly reputed exporter, manufacturer, and trader of Anti Vibration Rubber pads at the Best Price in Haryana. High-quality and technologically advanced anti-vibration pads for all industrial machines. Our anti-vibration rubber pads are made of durable and long-lasting, high-quality materials. They are suitable for use in a variety of settings, including industrial, commercial, and residential applications. Whether you need anti-vibration pads for heavy machinery or household appliances, we have got you covered. Our anti-vibration rubber pads come in different sizes and shapes to suit your specific needs. We understand that every customer has unique requirements, and we are committed to providing customized solutions that meet their needs. Our products are designed to offer maximum vibration isolation and noise reduction, ensuring a comfortable and peaceful environment. We take pride in offering our customers the best price for our high-quality products. Our prices are competitive, and we strive to provide value for money. Additionally, we offer discounts and special offers from time to time, allowing our customers to save even more. To purchase our anti-vibration rubber pads and Rubber Air Spring Isolators, simply visit our website or contact us for more information. Our knowledgeable team is always on hand to help you choose the best product for your needs and answer any questions you may have. Order your anti-vibration rubber pads today and experience the difference in vibration and noise reduction.

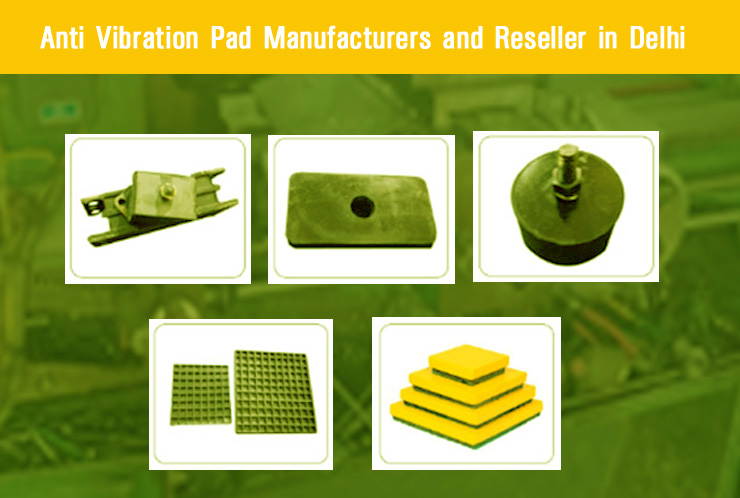

Anti Vibration Pad Manufacturers And Reseller in Haryana

Anti-vibration pads are essential in reducing noise and vibration situations in ministry, helping to ameliorate effectiveness and dragging the lifetime of the equipment. However, there are several manufacturers and resellers to choose from, If you are in request anti-vibration pads. We are a leading and highly reputed exporter, manufacturer, importer, wholesaler, distributor, supplier, and trader of Anti Vibration Pad Manufacturers And Reseller in Delhi. High quality and technologically advanced anti vibration pads for all industrial machines. Unick Vibration is a leading manufacturer of anti-vibration pads, furnishing a wide range of high-quality results suitable for colorful artificial operations. Another prominent manufacturer and supplier of anti-vibration pads are Unick Vibration., offering top-notch results for vibration control. In addition to manufacturers, there are also several resellers of anti-vibration pads in the request. Vibration Insulation Products is a well-known reseller of anti-vibration pads, furnishing a range of results for HVAC systems, creators, and heavy ministry. Reliable Engineers is another Delhi- grounded manufacturer and supplier of anti-vibration pads, offering high-quality results for power presses, air compressors, and forging hammers. Acousta- fil is a leading manufacturer and supplier of anti-vibration pads, offering a range of products suitable for colorful artificial operations, including pumps, motors, and creators. When choosing an anti-vibration pad manufacturer or reseller, it’s important to probe and compare prices and quality. Look for a supplier with a good character and a track record of furnishing dependable results for artificial operations. In summary,anti-vibration pads are pivotal in reducing noise and vibration situations in ministry, and there are several manufacturers and resellers to choose from in the request. Do your exploration and compare prices and quality to find the stylish result for your requirements.

Anti Vibration Pads Dealers

As an anti-vibration pad dealer, you play an important role in providing high-quality products and services to your customers. Anti-vibration pads are essential in reducing noise pollution and extending the lifespan of machinery by reducing wear and tear on moving parts. Here are some key things to consider as an anti-vibration pad dealer: We are a leading and highly reputed exporter, manufacturer, importer, wholesaler, distributor, supplier, and trader of Anti Vibration Pads Dealers. High quality and technologically advanced anti vibration pads for all industrial machines. By focusing on these key areas, you can position your business as a leading anti-vibration pad dealer and help your customers achieve optimal performance and efficiency from their machinery.