Industrial machinery plays a vital role in manufacturing, construction, transportation, and heavy engineering sectors. However, excessive vibration remains one of the biggest challenges, leading to noise, equipment wear, structural damage, and reduced operational efficiency. Modern vibration control solutions are evolving rapidly to address these concerns more effectively than ever before.

Why Vibration Control Matters in Heavy Industries

Uncontrolled vibrations can shorten machine lifespan, loosen fasteners, damage nearby structures, and create unsafe working conditions. Industries such as automotive manufacturing, railways, aerospace, power plants, and precision engineering rely heavily on advanced vibration isolation systems to ensure smooth and stable machine performance.

Proper vibration management not only improves safety but also enhances productivity and lowers long-term maintenance costs.

Evolution of Vibration Isolation Materials

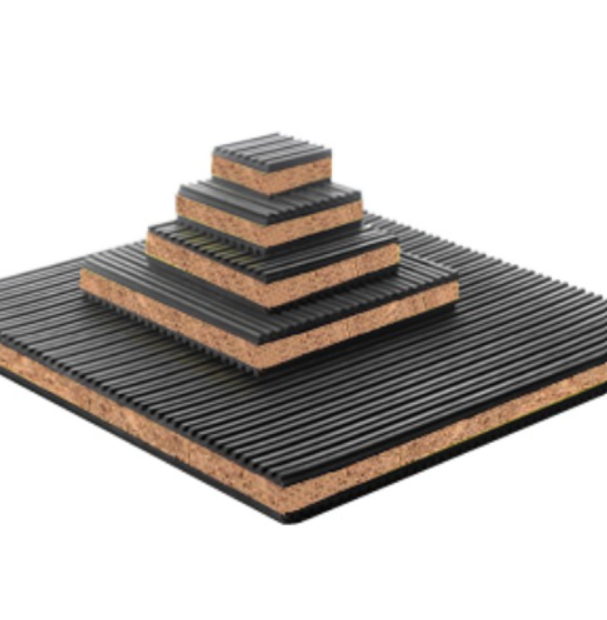

In the past, basic materials like natural rubber and cork were commonly used for vibration reduction. While effective to a certain extent, these materials had limitations in durability and load-bearing capacity.

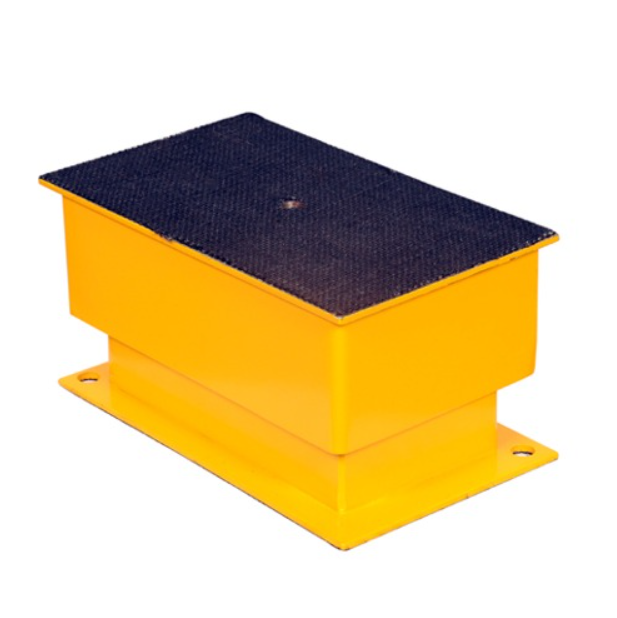

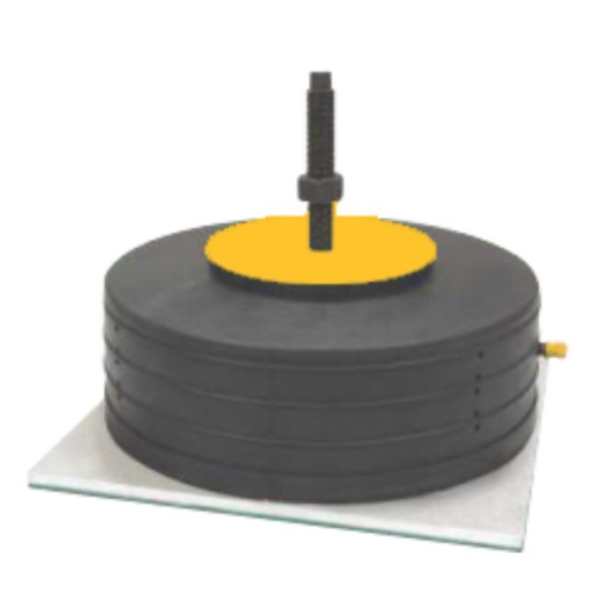

Today, anti vibration rubber pads are engineered using advanced elastomers, high-density polyurethane, and composite materials. These innovations offer better shock absorption, improved load distribution, and longer service life, even in demanding industrial environments.

Key Technological Advancements in Vibration Control

Advanced Material Engineering

Modern vibration pads are designed with multi-layered structures that enhance flexibility while maintaining strength. These materials perform consistently under heavy loads and extreme conditions.

Improved Damping Performance

New-generation vibration damping solutions are capable of absorbing a wider range of frequencies. This results in superior vibration isolation and noticeable noise reduction.

Sustainable Manufacturing Practices

Manufacturers are now focusing on eco-friendly materials and production techniques. Recyclable compounds and energy-efficient processes are becoming a standard part of vibration control solutions.

Application-Specific Design

Different machines require different vibration control approaches. Custom-engineered solutions ensure optimal performance based on load, environment, and usage conditions.

Applications Across Industries

Vibration isolation systems are widely used in:

- CNC machines and compressors

- HVAC systems

- Heavy industrial equipment

- Power generation units

In these applications, anti vibration rubber pads help minimize operational stress, improve precision, and maintain long-term stability.

Conclusion

The future of vibration control lies in smarter material selection, improved damping technology, and sustainable manufacturing. As industries continue to demand higher efficiency and reliability, vibration isolation solutions will play a critical role in protecting machinery and enhancing performance.

By adopting modern vibration control systems, businesses can achieve quieter operations, reduced maintenance costs, and improved machine longevity — all without compromising structural safety.