Machine vibration is one of the most common problems in industrial environments. Understanding the Common Causes of Machine Vibration is essential because excessive vibration not only affects machine performance but also reduces equipment lifespan, increases maintenance costs, and may cause safety issues. By identifying these root causes early, industries can take preventive steps and choose the right anti vibration pads for machinery to ensure smooth and stable operations.

At Unick Vibration, we provide reliable solutions to control industrial vibration effectively. Let’s understand the most common causes of machine vibration.

Imbalance in Rotating Parts

Imbalance occurs when the mass distribution in rotating components such as fans, motors, pulleys, or rotors is uneven. Even a small imbalance can generate strong centrifugal force during operation, leading to vibration.

Effects:

- Increased bearing wear

- Noise generation

- Reduced machine life

Regular dynamic balancing and proper installation of industrial vibration pads for machinery in India can significantly reduce vibration caused by imbalance.

Misalignment

Misalignment happens when two coupled shafts are not perfectly aligned. This is common in motors and pumps. Angular or parallel misalignment can create excessive vibration and stress on machine components.

Common signs of misalignment:

- Coupling damage

- High temperature in bearings

- Frequent breakdowns

Using quality anti vibration mounting solutions along with precision alignment helps prevent long-term damage.

Loose Components

Loose bolts, nuts, foundation cracks, or worn-out fittings can cause vibration. Over time, continuous vibration may further loosen components, worsening the problem.

Why it happens:

- Poor installation

- Weak foundation

- Lack of periodic maintenance

Installing proper anti vibration pads for machinery ensures better grip and reduces vibration transmission to the floor and surrounding structures.

Bearing Failure

Bearings support rotating shafts and help them move smoothly. When bearings wear out due to improper lubrication, contamination, or overload, vibration increases significantly.

Symptoms of bearing failure:

- Grinding noise

- Increased temperature

- Irregular vibration pattern

Timely replacement and vibration isolation systems can help extend equipment life.

Mechanical Resonance

Resonance occurs when machine operating frequency matches the natural frequency of the structure. This can amplify vibration dramatically.

Impact of resonance:

- Structural damage

- Severe noise

- Safety hazards

Proper vibration analysis and installation of industrial vibration pads for machinery in India can help isolate equipment and prevent resonance issues.

Improper Installation

Incorrect mounting, uneven flooring, or poor foundation design can lead to constant vibration. Even a well-designed machine can fail if not installed properly.

Using high-quality anti vibration pads for machinery during installation absorbs shocks and prevents vibration from spreading to nearby equipment.

External Environmental Factors

Nearby heavy machines, poor floor conditions, or uneven load distribution may also cause vibration. Industrial environments often have multiple machines operating simultaneously, which can create vibration transfer.

Industrial vibration pads act as shock absorbers, reducing the impact of external forces.

Why Vibration Control is Important

Ignoring machine vibration can result in:

- Increased maintenance cost

- Energy loss

- Reduced productivity

- Unexpected breakdowns

- Safety risks

That’s why industries across India rely on trusted brands like Unick Vibration for effective vibration control solutions.

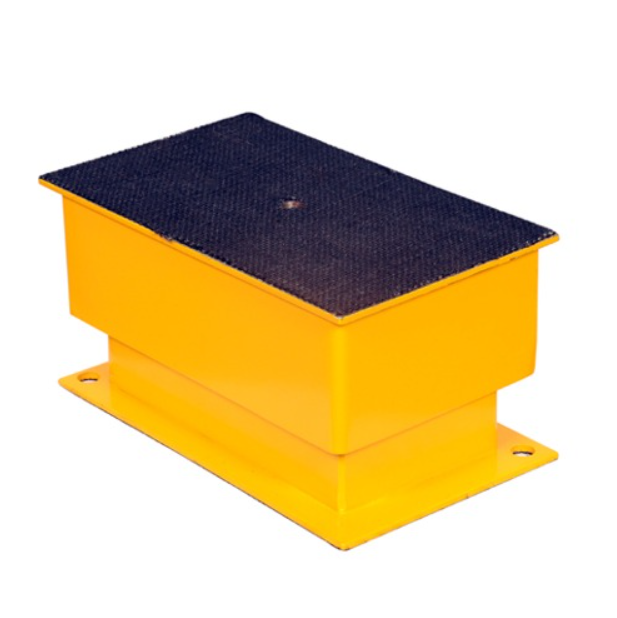

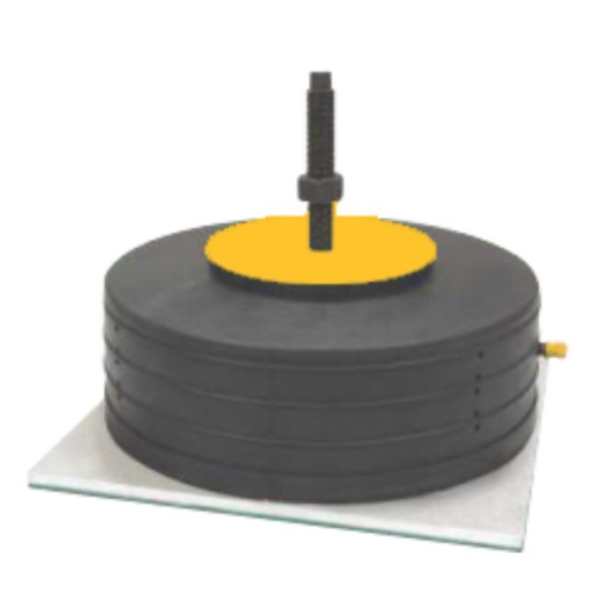

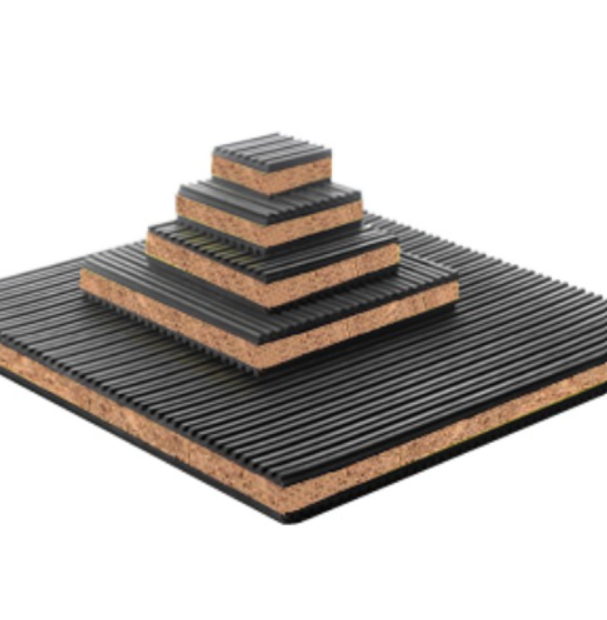

How Anti Vibration Pads Help

Anti vibration pads are specially designed to:

- Absorb shock and impact

- Reduce noise levels

- Improve machine stability

- Extend equipment lifespan

- Protect floors and foundations

Choosing the right anti vibration pads for machinery ensures better performance and long-term reliability. If you are searching for durable and high-performance industrial vibration pads for machinery in India, Unick Vibration offers a wide range of solutions suitable for generators, compressors, pumps, CNC machines, and heavy industrial equipment.

Conclusion

Machine vibration is a serious issue that should never be ignored. Causes like imbalance, misalignment, loose components, bearing failure, resonance, and improper installation can significantly affect industrial operations.

By understanding these causes and investing in the right vibration control solutions, industries can maintain efficiency, safety, and long-term productivity.

Unick Vibration is committed to providing premium quality anti vibration pads designed to meet industrial standards across India. If you want reliable and long-lasting vibration control solutions, choosing the right product today can save significant maintenance costs tomorrow.