Industrial machinery requires precise alignment and stable support to operate efficiently. Uneven floors or vibrations can cause operational errors, noise, and long-term machine damage. Industrial levelling pads are designed to address these challenges by ensuring proper machine balance, improving operational accuracy, and extending equipment life.

This guide explains the basics of levelling pads, their types, common applications, and key factors to consider when selecting the right solution for your machinery.

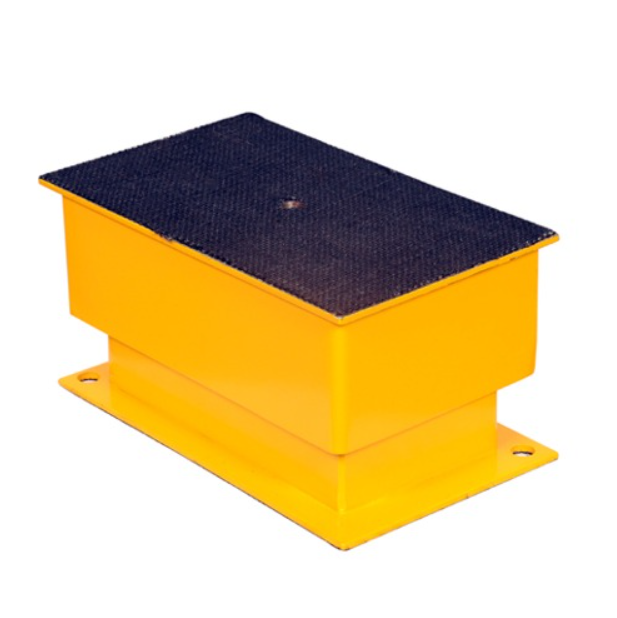

What Are Industrial Levelling Pads?

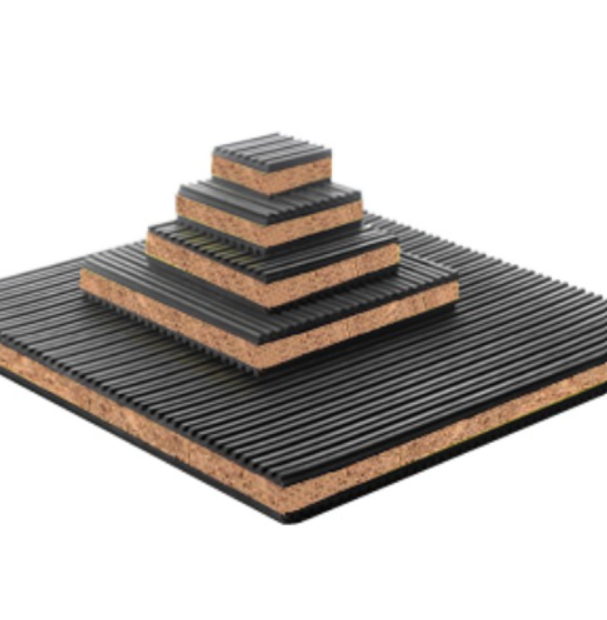

Industrial levelling pads are adjustable support components installed beneath machines to compensate for floor irregularities and ensure proper alignment. They help distribute machine load evenly while minimizing vibration and operational stress.

For businesses looking for reliable and high-quality solutions, Unick Vibration provides engineered industrial levelling pads that deliver consistent performance.

To learn more about vibration control, you can explore the role of anti vibration levelling pads in industrial machinery.

Types of Levelling Pads Used in Industry

Different industrial setups require different levelling pad types. Common types include:

Cast Iron Levelling Pads

- Suitable for light to medium-duty machinery

- Strong load-bearing capacity

- Cost-effective and durable

Stainless Steel Levelling Pads

- Corrosion-resistant, ideal for hygienic or wet environments

- Perfect for food, pharma, and chemical industries

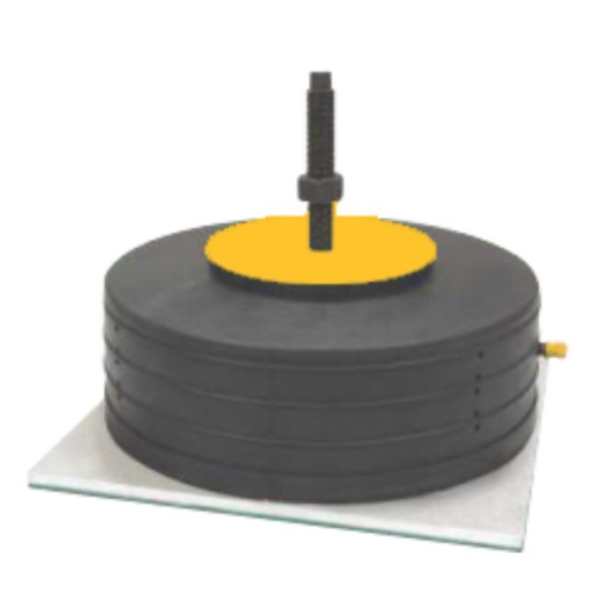

Adjustable Levelling Pads

- Threaded design allows precise height adjustment

- Ideal for uneven floors

- Enhances machine stability and alignment

Applications of Industrial Levelling Pads

Levelling pads are used in various industries, including:

- CNC machines and workshop machinery

- Compressors, pumps, and generators

- Printing, textile, and packaging machines

- Automation and plastic molding equipment

By reducing vibration and maintaining alignment, levelling pads improve machine efficiency and workplace safety.

How to Choose the Right Levelling Pads for Your Machinery

Selecting the correct levelling pads ensures long-term machine performance and reduces maintenance. Consider:

Load Capacity

Select pads that safely support the total machine weight during operation.

Floor Condition

Uneven or vibration-sensitive floors require adjustable levelling pads with proper support.

Material Selection

- Cast iron for general industrial use

- Stainless steel for corrosive or hygienic environments

For high-quality industrial solutions, explore Unick Vibration industrial levelling pads.

Why Quality Matters in Industrial Levelling Pads

Low-quality pads can cause misalignment, excessive vibration, and frequent maintenance issues. Trusted manufacturers like Unick Vibration focus on precision engineering and durable materials to ensure consistent industrial performance.

Conclusion

Industrial levelling pads are essential for maintaining machine stability, performance, and longevity. As a reputed manufacturer of levelling pads, we ensure the right type, material, and design are used to reduce vibration, improve alignment, and support long-term operational efficiency.