Proper levelling is critical for the smooth and accurate operation of industrial machines such as CNC machines, shaper machines, compressors, printing machines, textile machines, pressure die casting machines, and plastic injection moulding machines. Poor levelling can lead to vibration, loss of precision, increased wear, and frequent maintenance issues.

This is where levelling pads for industrial machines play an essential role, ensuring machine stability and long-term performance.

What Are Levelling Pads?

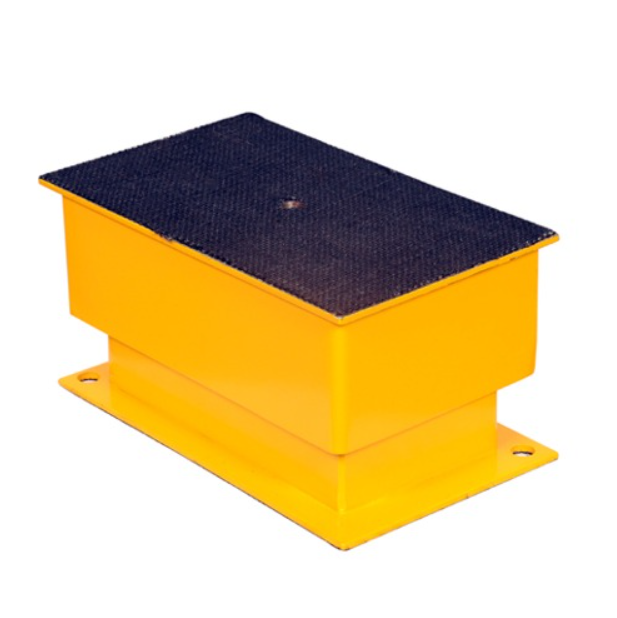

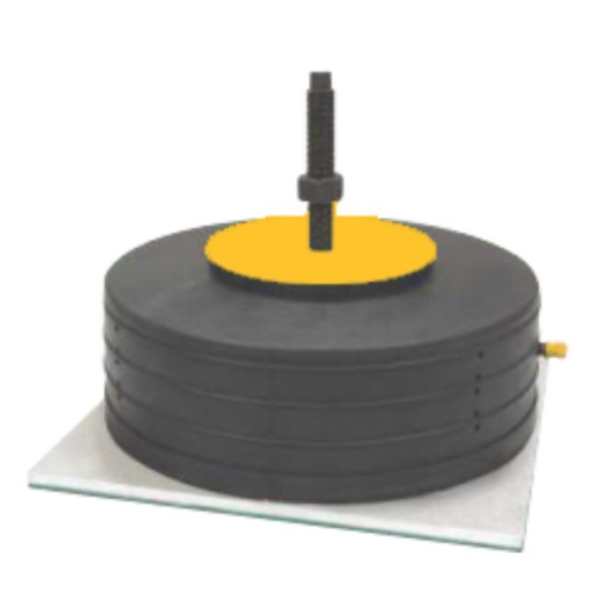

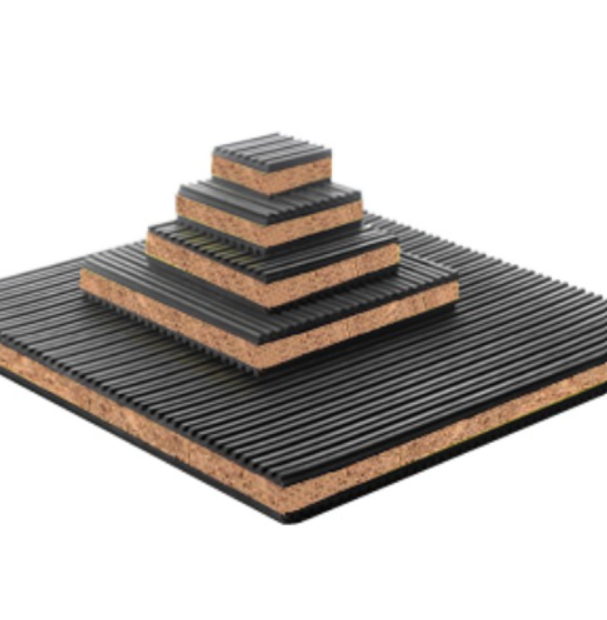

Levelling pads are specially designed supports installed under industrial machines to achieve accurate levelling and vibration control. They help distribute machine load evenly and reduce the need for expensive foundations or anchor bolts. High-quality levelling pads improve operational accuracy while protecting both the machine and the shop floor.

Why Levelling Pads Are Important for Industrial Machines

Industrial machines operate under heavy loads and continuous vibration. Without proper levelling, several problems can occur:

- Reduced machining accuracy

- Excessive vibration and noise

- Faster tool and component wear

- Increased maintenance and downtime

Using the right levelling pads ensures stable operation and consistent performance, even in demanding industrial environments.

Industrial Machines That Commonly Use Levelling Pads

Levelling pads are widely used across many industries and machine types, including:

- CNC Machines

- Tool Room Machines

- Shaper Machines

- Compressors

- Printing Machines

- Textile Machines

- Pressure Die Casting Machines

- Plastic Injection Moulding Machines

Whether the machine is light or heavy-duty, proper levelling is essential for safe and efficient operation.

How to Choose the Right Levelling Pads for Heavy Machines

When selecting levelling pads for industrial machinery, consider the following factors:

1 – Load Capacity

The levelling pad must support the total machine weight along with dynamic operating loads.

2 – Vibration Damping

Machines such as CNCs and compressors require levelling pads with good vibration-absorbing properties.

3 – Floor Condition

For uneven or weak floors, levelling pads with a wider base provide better stability.

4 – Height Adjustment

Smooth and precise height adjustment helps achieve accurate levelling during installation.

5 – Material Quality

Levelling pads made from high-grade steel, cast iron, and durable rubber components offer longer service life.

Benefits of Using Quality Levelling Pads

- Improved machine accuracy and repeatability

- Reduced vibration and operational noise

- Extended machine lifespan

- Easy installation and repositioning

- Lower foundation and installation costs

These benefits directly contribute to higher productivity and better production quality.

Real Installation Case Studies Using Unick Levelling Pads

Below are some real client installations where Unick levelling pads and mounts were successfully used to improve machine stability and performance.

Printing Machine Installed on Unick Levelling Mounts

A heavy-duty industrial printing machine was installed using Unick levelling mounts. The mounts helped reduce vibration and provided stable machine support, resulting in smoother operation and consistent print quality without the need for foundation bolts.

Lathe Machine Installed on Unick Levelling Pads

For a precision lathe machine,Unick levelling pads were used to achieve proper alignment and even load distribution. The installation reduced vibration during machining and improved surface finish and tool life. For enhanced stability, high-quality anti-vibration pads for CNC machines were also used, ensuring reliable and precise performance.

Plastic Grinding Machine Installed on Unick Levelling Pads

A plastic grinding machine was installed using Unick levelling pads to handle continuous vibration and heavy operating loads. The levelling pads improved machine stability, reduced vibration during grinding, and ensured smooth and efficient operation, helping extend machine life and maintain consistent output quality.

Choosing a Reliable Levelling Pads Manufacturer in India

Selecting an experienced levelling pads manufacturer in India is crucial for achieving consistent performance and reliability. A trusted manufacturer provides:

- Industrial-grade quality products

- Standard and custom levelling solutions

- Compliance with international quality standards

- Long-term durability and technical support

Working with the right manufacturer ensures your machines remain stable, accurate, and protected over time.

Final Words

Levelling pads are an essential component for industrial machines, helping maintain stability, precision, and safety. From CNC and shaper machines to plastic injection moulding and die casting machines, choosing the right levelling pads improves performance and reduces operational issues.

If you are looking for dependable levelling solutions, partnering with a trusted levelling pads manufacturer in India is a smart investment for long-term industrial success.

Get in touch with us today to explore our range of high-quality levelling pads and mounts, and ensure optimal performance for your industrial machines