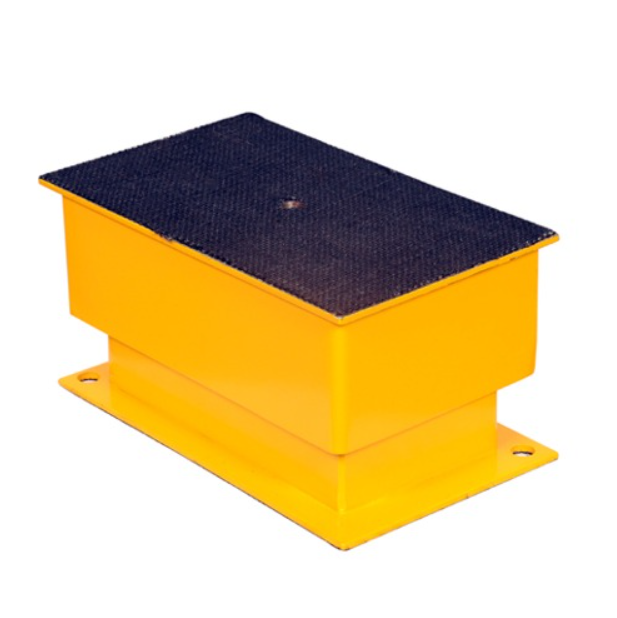

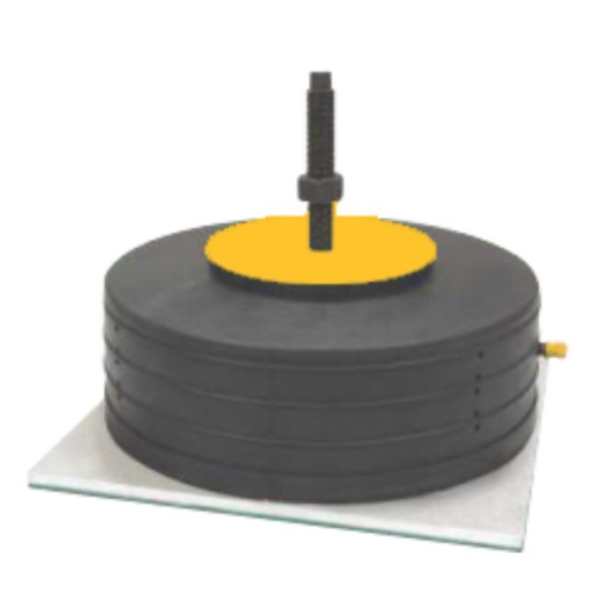

A slight vibration, an imbalance, or a misalignment can, in the competitive world of paper roll manufacturing, bring along production problems of a large scale. The stoppage of machines not only slows down the output but also directly raises the operating costs, affects the accuracy of the product and then adds up to the overall loss of profitability. This is the very reason why the industries have today turned towards advanced Heavy Duty Anti Vibration Pads solutions very quickly. Among them, Unick Spring Pads have been one of the most trusted parts for achieving stability, precision, and longevity in the machine.

Not only that, but they also play a very important part in keeping the whole process running smoothly even through heavy-duty, high-speed production cycles.

How Unick Spring Pads Minimize Vibrations and Prevent Costly Production Halts3

Vibration is one of the major concealed foes of paper roll production. If the machines are running at high speeds, even a minor instability can cause a series of failures. Unick Spring Pads are specially made to absorb shock, decrease vibration transmission, and keep machine alignment.

How They Help Reduce Downtime

- Unick Spring Pads stabilise rotating components and avoid misalignment.

- They soak up high-frequency vibrations that usually cause wear and friction.

- As a result, they lower the chances of sudden machine stoppage.

- They lessen vibration-induced damage thus reducing repair and replacement costs.

- Moreover, they keep delicate machine parts secured even during heavy operation.

Why It Matters

Paper roll production is dependent on a machine rhythm which is constant. A moment of disruption and the whole workflow is affected. Thus, controlling vibration is the same as reducing breakdowns, production delays, and getting smoother operations. Unick Spring Pads are the ones who have the deck; they are the ones who guarantee that all parts of the machine operate in the same way.

Boosting Paper Roll Precision: Why Stable Machine Operation Matters

Precision is a major issue indicator in the paper industry daintily pipelines. Mismatched paper rolls, varying thickness, or displaced layers cause material to be wasted to a large extent and customers unhappily so.

Stable machine operation ensures that:

- The applied pressure to the paper roll is always the same.

- The cutting, slitting, and rolling machines are all in perfect timing with one another.

- Machines keep producing quality rolls that are the same in each batch.

However, when stability is compromised, the roller mechanisms encounter increased friction which results in product defects. This is where Unick Spring Pads present their unmatched worth.

Unick Vibration Technology: Enhancing Machine Safety and Reducing Wear & Tear

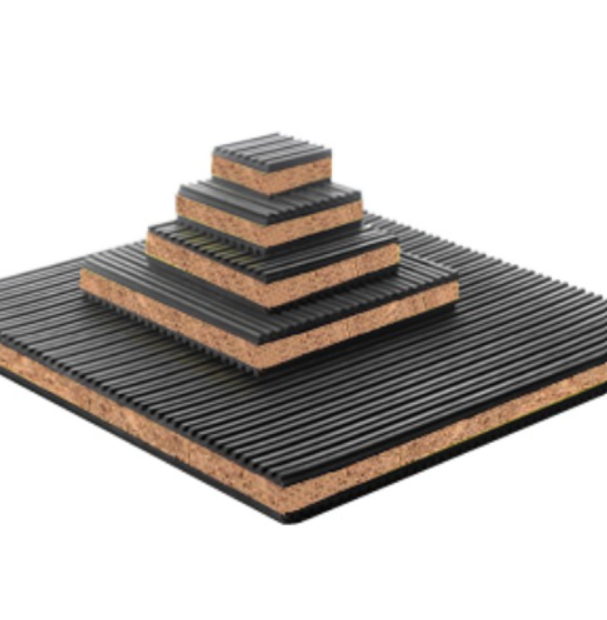

Unick’s technology for controlling vibration has been specifically designed, with a focus on long-term machinery safety, to offer such a benefit. The Spring Pads and Insulation Sheets created by them comprise of top-tier elastomers and springs that not only magnify load bearing capacity, but also facilitate shock absorption.

Key Contributions to Machine Safety:

- They minimize metal-to-metal contact, which results in no wear at all.

- They protect fragile interior parts from being affected by continuous vibration.

- Unick Vibration Technology keeps the machines properly aligned at all times.

- In addition, they avert excessive heat buildups that are brought about by vibrations.

Machine wear and tear somehow cause misalignment, loosened bolts, and even abrupt failures. Nevertheless, put the right vibration-control system in place, and such risks are immensely reduced. Unick Spring Pads are the ones that help machines to have longer lives and stay healthier, as well as extending the operational life and improving safety parameters.

Key Advantages of Using Spring Pads in High-Speed Paper Roll Manufacturing

Production lines that run at high speed need parts that can tolerate constant stress. Unick Spring Pads and Levelling Pad play a significant part by remaining robust even in the most challenging places.

The list of major benefits includes:

- Top-notch Vibration Isolation: Stabilizes machine movement even when it operates at the highest speed.

- Better Load Distribution: Stresses caused by the different loads are not concentrated on the machine components.

- Noise levels in production areas are less: it is a creation of the environment that is quieter and safer.

- Production accuracy is high: it guarantees that the paper will be correctly rotated and smoothly rolled with no defects at all.

- Machine lifespan is longer: it is less wear down that leads to breakdowns and thus, there is no frequent maintenance.

In addition to that, they also balance out the operation, thus maintaining the same output.

The manufacturers will have a reliable product at their disposal along with Unick Spring Pads that will guarantee every production run is of the same high standards in terms of speed, precision, and efficiency.

Increasing Output Efficiency Through Better Shock Absorption and Load Management

The machinery that rolls paper is subject to extreme pressure and tireless load cycles. Obviously, the machines to which the shock absorption technique is not advanced face jolts, imbalances, and friction-related damage. However, Unick Spring Pads are there to take on these problems and to make load management optimum.

What this means in terms of efficiency:

- For sudden speed changes or load shifts, they will take up the shock that is too much.

- They will take up the whole weight of the machine and share it equally, and this action will result in less stress on bearing and roller.

- As a result, there will be fewer unexpected breakdowns and less downtime.

- High-volume production will have been done while maintaining uniform speed.

- Also, friction will be minimized and so power consumption will be reduced.

Anti Vibration Stud Mounts Management of consistent loads gives machines maximum efficiency without the risk of overheating or loss of accuracy. Meanwhile, the smoother production line minimizes interruptions and better energy utilization which, in turn, contributes to a more cost-effective operation.

Conclusion

Unick Spring Pads are no longer seen as accessories; they are now indispensable parts of the modern paper roll manufacturing unit. By significantly lowering the vibration levels, softening the impact, and efficiently handling the heavy loads, and providing the required precision, they become the ideal choice of the industries in search of long-term performance and reliability. As a result, the businesses which want less period of inactivity of machines and highest production rate should apply Unick Spring Pads in their machines. The end result will be that with more stability the business will have better quality, more output, and more profit.

Make your production line modern with Unick Spring Pads now!

Machines working under the best conditions, the safest way, and the smoothest way, without unexpected breakdowns or expensive downtime. Our team is ready contact you for advanced vibration-control solutions and premium-quality Unick Spring Pads.

Stability is increased, accuracy is improved, and the paper roll production is taken to the next level.