Wedge Mounts

Wedge Mounts Manufacturer in India

Unick Vibration is a leading wedge mounts manufacturer in India and trusted anti vibration wedge mounts supplier in India, offering high-quality solutions for precise leveling and vibration reduction in heavy industrial machinery.

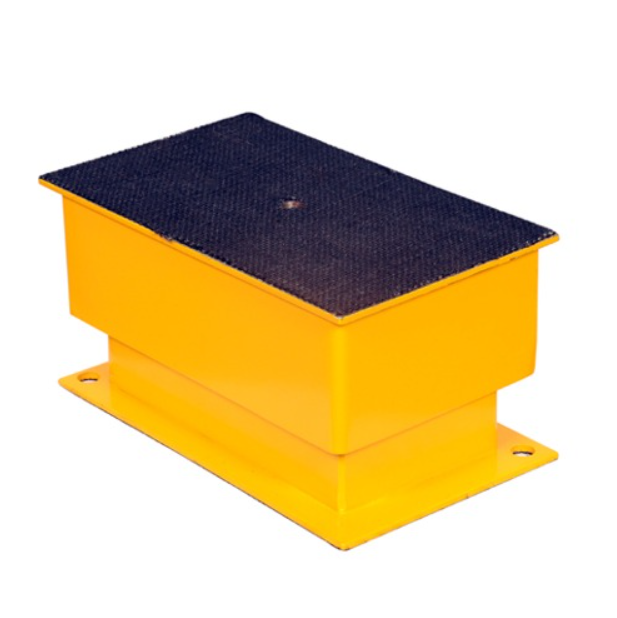

Unick Wedge Mounts are designed with three modular cast iron parts for superior performance. The center part features a leveling bolt that allows the middle wedge to move back and forth, ensuring high-precision leveling of machines.

Tightening the bolt increases the height

Loosening the bolt decreases the height

This mechanism provides easy and accurate adjustments. The two outer cast iron parts are inclined against the middle wedge, creating a large lifting force with minimal input torque. For smooth operation and long-lasting durability, high-quality low-fluorine grease is applied between all three parts.

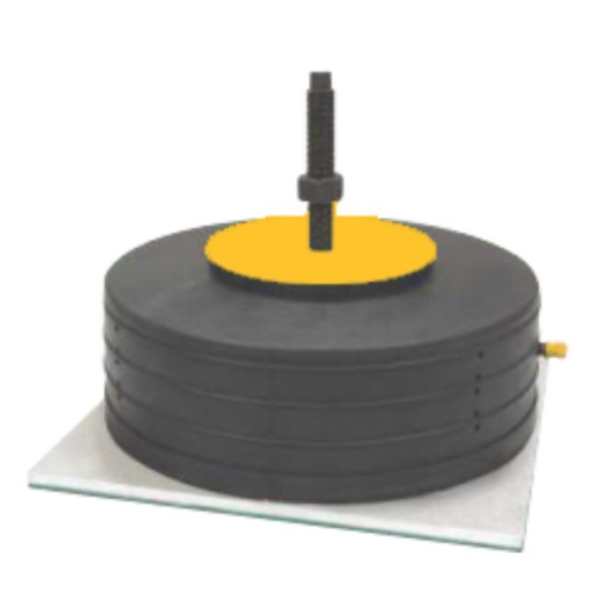

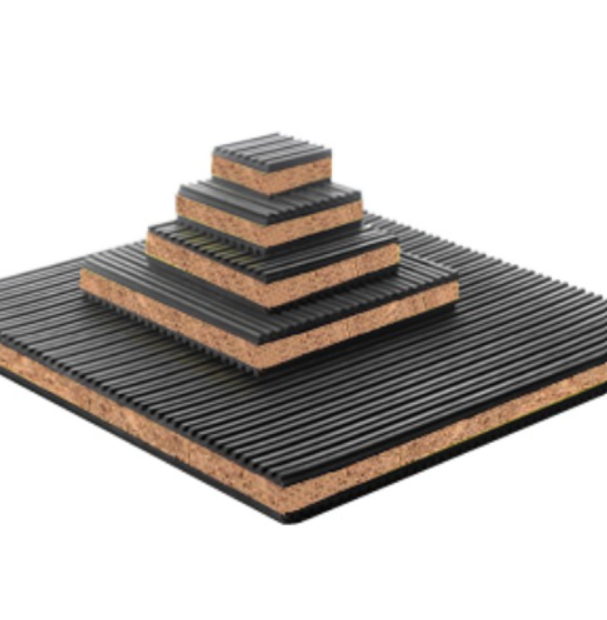

Cast iron itself is a natural vibration-damping material. For enhanced vibration absorption, Unick combines Anti Vibration Wedge Mounts with Insulation Sheets, applied on either one side or both sides of the mounts. Unick Wedge Mounts provide excellent surface solidity and rigidity and can be easily leveled even under the heaviest loads.

They offer both passive and active vibration isolation, ensuring stable machine performance. With precise and accurate leveling that is simple, fast, and efficient, these mounts also make it easier to clean the surrounding and underneath areas of the machine while facilitating convenient maintenance.

Types of Precision Anti Vibration Mount

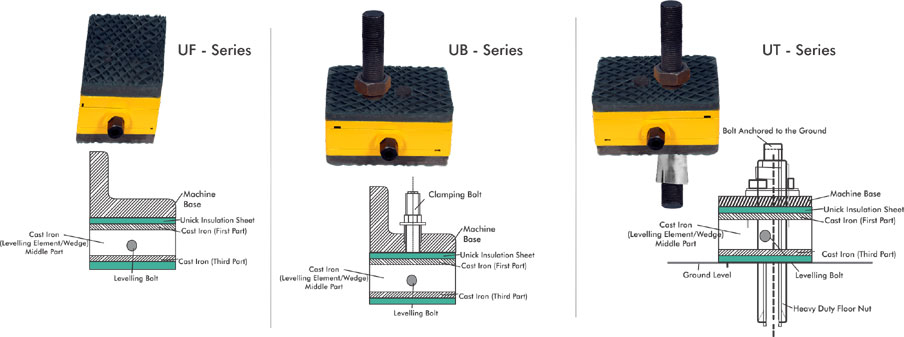

Unick Wedge Mounts are available in different models, with selection depending on the type of machine and its specific application:

UF (Unick Free Standing Wedge Mount): Suitable for machines that do not require anchoring.

UB (Unick Bolt-On Wedge Mount): Designed for machines with high axial thrust.

UT (Unick Anchored Wedge Mount): Ideal for heavy machines with eccentric motion or those that need to be firmly anchored to the ground.

Features:

|

|

|

Contact Us

|

|

|

Find the Ideal Wedge Mounts for Precision Stability

Achieve accurate leveling and vibration control with our premium wedge mounting solutions.