Common Causes of Machine Vibration

Machine vibration is one of the most common problems in industrial environments. Understanding the common causes of machine vibration is essential because excessive vibration not only affects machine performance but also reduces equipment lifespan, increases maintenance costs, and may cause safety issues. By identifying these root causes early, industries can take preventive steps and choose the right vibration control solutions to ensure smooth and stable operations. At Unick Vibration, we provide reliable solutions to control vibration effectively. Let’s understand the most common causes of machine vibration. Imbalance in Rotating Parts Imbalance occurs when the mass distribution in rotating components such as fans, motors, pulleys, or rotors is uneven. Even a small imbalance can generate strong centrifugal force during operation, leading to vibration. Effects: Regular dynamic balancing and proper vibration isolation techniques can significantly reduce vibration caused by imbalance. Misalignment Misalignment happens when two coupled shafts are not perfectly aligned. This is common in motors and pumps. Angular or parallel misalignment can create excessive vibration and stress on machine components. Common signs of misalignment: Using proper vibration isolation methods along with precision alignment helps prevent long-term damage. Loose Components Loose bolts, nuts, foundation cracks, or worn-out fittings can cause vibration. Over time, continuous vibration may further loosen components, worsening the problem. Why it happens: Installing proper vibration isolation materials ensures better grip and reduces vibration transmission to the floor and surrounding structures. Bearing Failure Bearings support rotating shafts and help them move smoothly. When bearings wear out due to improper lubrication, contamination, or overload, vibration increases significantly. Symptoms of bearing failure: Timely replacement and vibration isolation systems can help extend equipment life. Mechanical Resonance Resonance occurs when machine operating frequency matches the natural frequency of the structure. This can amplify vibration dramatically. Impact of resonance: Proper vibration analysis and vibration isolation systems can help isolate equipment and prevent resonance issues. Improper Installation Incorrect mounting, uneven flooring, or poor foundation design can lead to constant vibration. Even a well-designed machine can fail if not installed properly. Using proper vibration isolation materials during installation absorbs shocks and prevents vibration from spreading to nearby equipment. External Environmental Factors Nearby heavy machines, poor floor conditions, or uneven load distribution may also cause vibration. Industrial environments often have multiple machines operating simultaneously, which can create vibration transfer. Vibration isolation materials act as shock absorbers, reducing the impact of external forces. Why Vibration Control is Important Ignoring machine vibration can result in: That’s why industries across India rely on trusted brands like Unick Vibration for effective vibration control solutions. How Anti Vibration Pads Help Anti vibration pads are specially designed to: Choosing the right vibration isolation solution ensures better performance and long-term reliability. If you are looking for reliable vibration control products, Unick Vibration offers a wide range of solutions suitable for generators, compressors, pumps, CNC machines, and heavy industrial equipment. Conclusion Unick Vibration is committed to providing premium quality vibration control products designed to meet industrial standards across India. For advanced machine stability and performance, explore our anti vibration pads for machinery designed for heavy industrial applications.

Everything You Need to Know About Heavy Duty Levelling Pads

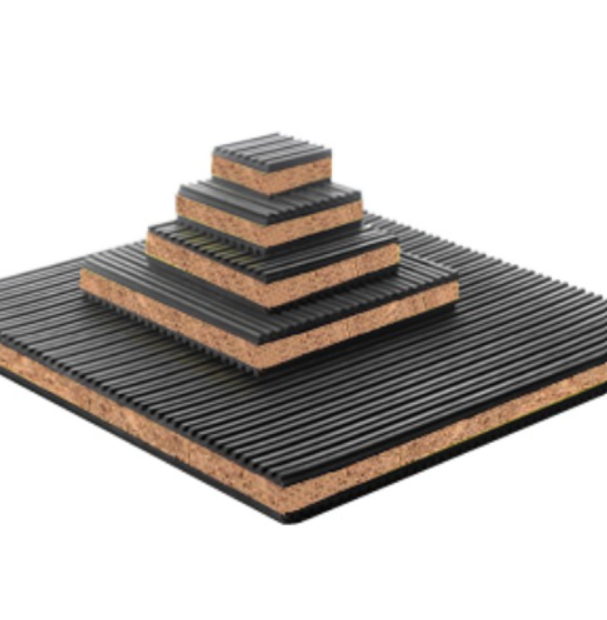

In industrial environments, even minor machine imbalance can lead to serious operational problems over time. Heavy duty levelling pads play a critical role in ensuring that machinery remains stable, properly aligned, and isolated from harmful vibrations. Rather than being a basic accessory, these components directly influence machine accuracy, performance consistency, and long-term reliability. Choosing the right Heavy Duty Levelling Pads Manufacturer India helps industries achieve better operational control while minimizing wear and maintenance issues. How Heavy Duty Levelling Pads Improve Machine Precision In industrial terms, precision refers to a machine’s ability to repeatedly perform operations with consistent accuracy and minimal deviation. When a machine is not properly levelled, uneven weight distribution causes micro-movements during operation. These small shifts reduce precision by affecting tool alignment, output consistency, and calibration stability. Heavy duty levelling pads correct floor irregularities and evenly distribute machine load. This stable foundation ensures that machines maintain their calibrated position, resulting in precise, repeatable performance—especially important in CNC machining, printing, and automated production systems. Common Problems Caused by Poor Machine Levelling Improper levelling can introduce multiple operational issues that often go unnoticed until damage occurs. Some common problems include: These issues highlight why industries increasingly rely on Industrial Anti Vibration Levelling Pads to isolate machinery from structural vibrations and maintain operational balance. Engineering Design Behind Anti Vibration Levelling Pads The performance of levelling pads depends largely on their engineering design. A well-designed pad typically consists of a high-strength steel threaded stud combined with a vibration-damping base made from rubber or elastomeric compounds. The vibration-absorbing base works by converting mechanical energy into heat, reducing the amount of vibration transmitted to the floor. At the same time, the rigid metal components ensure load stability. A reliable anti vibration levelling pads manufacturer focuses on optimizing this balance between flexibility and strength to achieve effective vibration isolation. Selecting the Right Levelling Pad for Heavy Machinery Not all levelling pads are suitable for every machine. Selection should be based on factors such as machine weight, dynamic load during operation, floor condition, and environmental exposure. Using a pad with insufficient load capacity can reduce vibration absorption and compromise stability. A trusted Levelling Pad Manufacturer in India typically provides technical specifications and load charts to help industries select the correct pad type. This ensures optimal performance without overstressing the levelling system. Installation and Load Considerations for Industrial Levelling Pads Proper installation is essential to achieve the full benefits of levelling pads. Pads should be positioned at manufacturer-recommended load points, and the machine should be gradually adjusted to ensure even weight distribution. Maintaining an appropriate safety margin—usually operating below the maximum rated load—helps extend the life of the pads and ensures consistent vibration control under continuous operation. Long-Term Cost Benefits of Using Quality Levelling Pads Although levelling pads may appear to be a small investment, their long-term impact is significant. Proper vibration control reduces mechanical stress, lowers maintenance costs, and minimizes unplanned downtime. Manufacturers such as Unick Vibration focus on engineering solutions that support long-term machine stability, helping industries improve productivity while controlling operational costs. Conclusion Heavy duty levelling pads are essential components in modern industrial setups, supporting machine precision, vibration isolation, and structural protection. By understanding their engineering design, selection criteria, and installation requirements, industries can make informed decisions that enhance machine performance and operational efficiency.

Top Industrial Vibration Damping Spring Pads to Improve Machine Stability

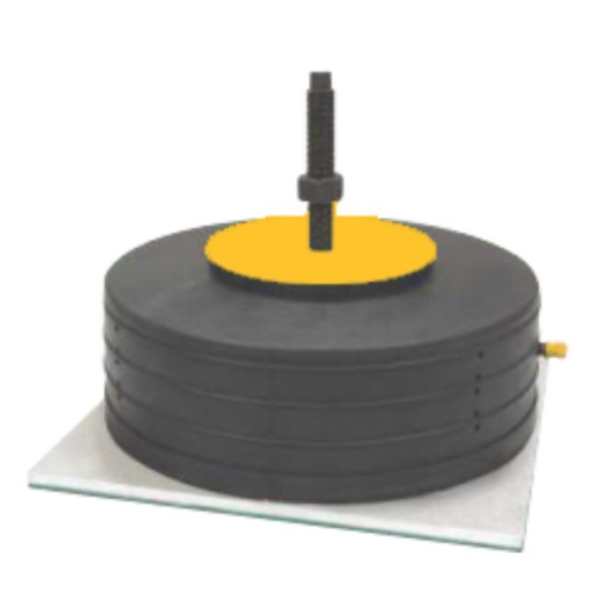

Excessive vibrations in industrial machinery can reduce precision, damage equipment, and create an unsafe, noisy work environment. To maintain stability and efficiency, industries rely on industrial vibration damping spring pads, which absorb shocks, reduce vibration, and ensure smoother machine operation. Using these pads helps extend machine life, reduce maintenance costs, and create a safer workplace. Unick Vibration offers durable and reliable solutions designed to handle the unique challenges of modern industrial equipment. From heavy machinery to precision tools, these pads provide effective vibration damping and enhanced operational stability. Why Industrial Machines Need Vibration Damping Spring Pads Vibrations can lead to: By installing high-quality spring pads, industries can protect their equipment, maintain smooth operation, and ensure consistent productivity. Features of Industrial Vibration Damping Spring Pads Shock Absorption: Minimizes vibrations and impacts from heavy loads. Durable Materials: Ensures long-lasting performance under industrial conditions. Noise Reduction: Provides a quieter and safer working environment. Easy Installation: Quick setup without special tools. Benefits of Using Vibration Damping Spring Pads Ideal Use Cases These pads are suitable for machines operating under heavy loads, high-speed motors, or precision equipment where stability and noise reduction are critical. They protect your investment while ensuring consistent, efficient performance. Conclusion Investing in high-quality industrial vibration damping spring pads is essential for any industrial setup. With Unick Vibration, a trusted Anti Vibration Spring Pad Manufacturer India, businesses can enjoy enhanced machine stability, reduced maintenance, and longer-lasting machinery, making them a smart choice for modern industries.

Industrial Levelling Pads: Types, Uses & Selection Guide

Industrial machinery requires precise alignment and stable support to operate efficiently. Uneven floors or vibrations can cause operational errors, noise, and long-term machine damage. Industrial levelling pads are designed to address these challenges by ensuring proper machine balance, improving operational accuracy, and extending equipment life. This guide explains the basics of levelling pads, their types, common applications, and key factors to consider when selecting the right solution for your machinery. What Are Industrial Levelling Pads? Industrial levelling pads are adjustable support components installed beneath machines to compensate for floor irregularities and ensure proper alignment. They help distribute machine load evenly while minimizing vibration and operational stress. For businesses looking for reliable and high-quality solutions, Unick Vibration provides engineered industrial levelling pads that deliver consistent performance. To learn more about vibration control, you can explore the role of anti vibration levelling pads in industrial machinery. Types of Levelling Pads Used in Industry Different industrial setups require different levelling pad types. Common types include: Cast Iron Levelling Pads Stainless Steel Levelling Pads Adjustable Levelling Pads Applications of Industrial Levelling Pads Levelling pads are used in various industries, including: By reducing vibration and maintaining alignment, levelling pads improve machine efficiency and workplace safety. How to Choose the Right Levelling Pads for Your Machinery Selecting the correct levelling pads ensures long-term machine performance and reduces maintenance. Consider: Load Capacity Select pads that safely support the total machine weight during operation. Floor Condition Uneven or vibration-sensitive floors require adjustable levelling pads with proper support. Material Selection For high-quality industrial solutions, explore Unick Vibration industrial levelling pads. Why Quality Matters in Industrial Levelling Pads Low-quality pads can cause misalignment, excessive vibration, and frequent maintenance issues. Trusted manufacturers like Unick Vibration focus on precision engineering and durable materials to ensure consistent industrial performance. Conclusion Industrial levelling pads are essential for maintaining machine stability, performance, and longevity. As a reputed manufacturer of levelling pads, we ensure the right type, material, and design are used to reduce vibration, improve alignment, and support long-term operational efficiency.

Levelling Pads for Industrial Machines: CNC, Shaper, Press and More

Proper levelling is critical for the smooth and accurate operation of industrial machines such as CNC machines, shaper machines, compressors, printing machines, textile machines, pressure die casting machines, and plastic injection moulding machines. Poor levelling can lead to vibration, loss of precision, increased wear, and frequent maintenance issues. This is where levelling pads for industrial machines play an essential role, ensuring machine stability and long-term performance. What Are Levelling Pads? Levelling pads are specially designed supports installed under industrial machines to achieve accurate levelling and vibration control. They help distribute machine load evenly and reduce the need for expensive foundations or anchor bolts. High-quality levelling pads improve operational accuracy while protecting both the machine and the shop floor. Why Levelling Pads Are Important for Industrial Machines Industrial machines operate under heavy loads and continuous vibration. Without proper levelling, several problems can occur: Using the right levelling pads ensures stable operation and consistent performance, even in demanding industrial environments. Industrial Machines That Commonly Use Levelling Pads Levelling pads are widely used across many industries and machine types, including: Whether the machine is light or heavy-duty, proper levelling is essential for safe and efficient operation. How to Choose the Right Levelling Pads for Heavy Machines When selecting levelling pads for industrial machinery, consider the following factors: 1 – Load Capacity The levelling pad must support the total machine weight along with dynamic operating loads. 2 – Vibration Damping Machines such as CNCs and compressors require levelling pads with good vibration-absorbing properties. 3 – Floor Condition For uneven or weak floors, levelling pads with a wider base provide better stability. 4 – Height Adjustment Smooth and precise height adjustment helps achieve accurate levelling during installation. 5 – Material Quality Levelling pads made from high-grade steel, cast iron, and durable rubber components offer longer service life. Benefits of Using Quality Levelling Pads These benefits directly contribute to higher productivity and better production quality. Real Installation Case Studies Using Unick Levelling Pads Below are some real client installations where Unick levelling pads and mounts were successfully used to improve machine stability and performance. Printing Machine Installed on Unick Levelling Mounts A heavy-duty industrial printing machine was installed using Unick levelling mounts. The mounts helped reduce vibration and provided stable machine support, resulting in smoother operation and consistent print quality without the need for foundation bolts. Lathe Machine Installed on Unick Levelling Pads For a precision lathe machine,Unick levelling pads were used to achieve proper alignment and even load distribution. The installation reduced vibration during machining and improved surface finish and tool life. For enhanced stability, high-quality anti-vibration pads for CNC machines were also used, ensuring reliable and precise performance. Plastic Grinding Machine Installed on Unick Levelling Pads A plastic grinding machine was installed using Unick levelling pads to handle continuous vibration and heavy operating loads. The levelling pads improved machine stability, reduced vibration during grinding, and ensured smooth and efficient operation, helping extend machine life and maintain consistent output quality. Choosing a Reliable Levelling Pads Manufacturer in India Selecting an experienced levelling pads manufacturer in India is crucial for achieving consistent performance and reliability. A trusted manufacturer provides: Working with the right manufacturer ensures your machines remain stable, accurate, and protected over time. Final Words Levelling pads are an essential component for industrial machines, helping maintain stability, precision, and safety. From CNC and shaper machines to plastic injection moulding and die casting machines, choosing the right levelling pads improves performance and reduces operational issues. If you are looking for dependable levelling solutions, partnering with a trusted levelling pads manufacturer in India is a smart investment for long-term industrial success. Get in touch with us today to explore our range of high-quality levelling pads and mounts, and ensure optimal performance for your industrial machines

Need Custom Spring Pads in Haryana? Unick’s Raschel Machine Enables Precision

Industrial machines create vibrations during their daily functioning. In case vibrations are not managed properly, they can harm the machines, floors, and adjacent equipment. Consequently, the industries have now started to pay attention towards the spring pads as their machines’ protectors. Nevertheless, each machine has its own characteristics. Thus, the customized spring pads are more effective than the standard ones. Unick Vibration manufactures custom spring pads in Haryana by employing its state-of-the-art Raschel machine, which is known for its high accuracy as well as reliable performance. This leads to a scenario, where the industries benefit from improved safety, longer machine life, and uninterrupted operation. Why Custom Spring Pads Are Essential for Industrial Efficiency Standard spring pads may not be appropriate for machine weight or vibration level. As a result, they usually do not provide the right amount of control over vibration. Conversely, custom spring pads are manufactured as per the specifications of the machine. Advantages of Custom Spring Pads Thus, custom-made spring pads become an indispensable part of industrial efficiency. How Unick’s Raschel Machine Delivers Precision Manufacturing Precision is one of the major factors for the success of vibration control products. Therefore, Unick Vibration relies on a cutting-edge Raschel machine for manufacturing spring pads. The machine guarantees the same structure, proper thickness and good bonding throughout. Therefore, the performance of each spring pad is always at a consistent level. Advantages of Raschel Machine Technology: Thus, the Raschel machine enables Unick to offer highly precise custom spring pads. Unick Vibration Technology: Enhancing Performance of Every Spring Pad Unick Vibration aims at machine performance enhancement through the use of advanced Heavy Duty Anti Vibration Pads solutions. Thus, their spring pads are subjected to real industrial conditions testing. There are several ways Unick Spring Pads improve performance: As a result, Unick spring pads are beneficial both for machines’ health and production results. Choosing the Right Material for Long-Lasting Spring Pads The life of a spring pad is directly influenced by the quality of the material. If a poor quality material is used, the pads will sooner or later crack, deform or lose elasticity. This is why Unick is very picky about materials and only selects the ones suitable for the machine usage and environment. Main Material Selection Factors: Therefore, the selection of the right materials leads to the production of durable spring pads and Levelling Pad. Haryana Manufacturers Rely on Custom Solutions for Quality Results The state of Haryana is full of various industries like manufacturing, engineering, textiles, and automotive. Due to the heavyweight machines used in these industries, vibration control is a major requirement. Reasons Why Haryana Industries Prefer Unick Custom Spring Pads: Thus, Unick Vibration is a reliable industry partner in Haryana. Conclusion Custom spring pads are a necessity in the modern industrial machine. In conclusion, they control vibration, protect machinery, and increase production. Unick Vibration, equipped with a state-of-the-art Raschel machine technology, supplies Haryana with precision-crafted custom spring pads and Rubber Pads. Consequently, industries get better performance, lower maintenance costs, and a longer lifespan. Do you need custom spring pads of the highest quality in Haryana? Better control of vibrations translates to increased productivity.

Protecting Your Investment: Unick Spring Pads for Aluminium Shredding Machines

Aluminium shredding machines do to the metal a big cut, crushing, and processing with powerful force and continuous motion under great pressure. This consequently results in the machines producing high vibration and noise while operating. If the vibration is not properly managed, it can eventually lead to slow damage of the machine and a hike in the costs of repair. This is the very reason why Unick Spring Pads are a necessity. They not only minimize the vibration but, at the same time, befriend the parts of the machine and guarantee the seamless operations of the aluminum shredding machines. To put it in simple terms, Unick Spring Pads are the silent partners of industries in terms of saving costs, enhancing safety, and keeping their machines usable in the long run. Why Quality Spring Pads Are Crucial for Aluminium Shredding Machines Aluminium shredding machines generate a very powerful vibration as they process metal. The result is that this vibration can move into the machine’s framework and the floor. Eventually, this will lead to the damage of the machine and the reduction of its lifespan. For one thing, good spring pads absorb the vibration. For another thing, they stabilize the machine. So, high-quality spring pads are a must for a safe and efficient operation. Quality Unick Spring Pads will help you as follows: In brief, mighty spring pads protect both the machine and the people working around it. Enhancing Machine Longevity with Unick Vibration Solutions Unick Spring Pads are made specifically for heavy industrial machines such as aluminium shredders. Unlike common pads, they are intended for use in situations where there is a constant load and strong vibrations without compromising their shape. This is the reason Unick Spring Pads support machines and keep them in alignment throughout the years. Moreover, Unick also employs tough materials that resist wear and tear. This is a great advantage for industries as it minimizes the need for frequent replacements and maintains problems. Reducing Operational Noise and Vibrations Effectively Noise and vibrations can produce uncomfortable and unsafe working conditions. On the other hand, Unick Spring Pads and Heavy Duty Anti Vibration Pads come to the rescue and assist in the control of both situations. They minimise vibration and noise in three different ways: Thus, the machines used for shredding aluminium are less noisy, more controlled, and run smoothly. Cost Savings Through Durable and Reliable Spring Pads It is a fact that many industries are unaware of that vibration causes the operating expenses to be increased. However, the truth is that vibration leads to unreliable machines and consequently higher maintenance costs. Unick Spring Pads are designed to last for a very long time. Their long life allows industries to save money over time. They come with cost-saving benefits: Thus, Unick Spring Pads are a wise investment for industrial operations. Installation and Maintenance Tips for Optimal Performance Perfect installation is the key to spring pads working properly. The good news is Unick Spring Pads and Levelling Pad are easy to install and service. For the best results, remember to follow these simple tips: The industries spring pads to long-lasting performance if these steps are followed. Conclusion Aluminium shredding machines rob the industries of their value if they turn out to be too noisy or vibratory, besides the fact that such machines will not perform well if the noise and vibration are not effectively controlled. Unick Spring Pads present the simplest, yet most effective way to get rid of these problems. They absorb vibrations, shield machine components, reduce noise and increase the overall productivity of the operation. More significantly, they assist the industries in safeguarding their investments while keeping the operations running smoothly. In the long term, Unick Spring Pads selection implies improved performance, cost reduction, and a safer workplace. Do you want your aluminium shredding machines to vibrate less? Unick Spring Pads are the answer for you as they come with dependable vibration control and provide machine protection for the long run. Connect with Unick Vibration now to obtain the appropriate spring pad solution for your equipment. Reduce vibrations, prolong machine life, and enhance performance by choosing Unick.

How to Choose the Right Unick Spring Pad for Your Industrial Shearing Machine

Industrial shearing machines work under very harsh conditions with high pressure, repetitive motion, and constant vibration. Therefore, even small problems related to vibration can turn into significant failures in the operation, loss of precision, and increased maintenance expenses. Hence, the selection of a suitable spring pad is not only a technical decision but also a strategic investment in the machine’s lifetime and productivity. Unick Spring Pads are made with cutting-edge vibration isolation technology to deal with these problems. This guide will cover everything you need to know to select the appropriate Unick Spring Pad for your industrial shearing machine, thus guaranteeing the highest performance, minimum downtime, and long-term efficiency. Understanding the Role of a Spring Pad in Industrial Shearing Machines Spring pads are indispensable to the stabilization of industrial machinery, particularly for heavy-duty machines such as shearing machines, amongst others. Their primary function is to cushion the impact between the machine and the ground. In addition, a well-chosen spring pad can help with the following: As a result, the spring pad becomes an unobtrusive but potent aid to the overall machine efficiency. Key Factors to Consider When Selecting a Unick Spring Pad It is essential to consider multiple operational factors very thoroughly before making a choice regarding the Unick Spring Pad. Before arriving at a decision, weigh these points carefully: Thus, disregarding these factors when choosing a spring pad may lead to unstable and less productive machine operation. How Unick Vibration Technology Enhances Machine Performance Unick Vibration is specifically developed for the Heavy Duty Anti Vibration Pads industrial sector to provide the ultimate vibration control. The Unick spring pads are not like the regular ones, as they are the result of precision engineering for the hardest applications. The main performance benefits are: Thus, the Unick spring pads are a direct contribution to increased productivity and a lower level of operational risks. Material and Durability: Ensuring Long-Lasting Efficiency The quality of the material is the main factor that determines how well the spring pad performs and how long it lasts. Unick spring pads are made of high-quality materials that are meant to last in the toughest industrial conditions, which is why the company uses such materials in its products. The advantages of the material and durability are as follows: In the end, the use of durable materials means that the maintenance cost will be lower and the performance will be more consistent in the long run. Installation Tips and Maintenance for Optimal Results No matter how good the spring pad is, it will not work to its full potential if it is not set up and taken care of properly. That is why the correct installation and regular checks are very important. The best practices for installation include: Maintenance tips include: Following these procedures will allow you to obtain the most out of your Unick Spring Pads both in terms of efficiency and lifespan. Conclusion The selection of an appropriate Unick Spring Pad and Anti Vibration Wedge Mount Pads for your industrial shearing machine is a vital choice since it has a direct impact on performance, safety, and costs associated with operations. To sum up, the main factors to lower vibration and achieve optimal results are understanding their control requirements, analysing machine specifications, and using high-quality materials. What is more, Unick Spring Pads are equipped with cutting-edge vibration isolation technology and have the advantage of being extremely durable and providing reliable performance, thus making them a secure solution for contemporary industrial applications. If they are chosen and installed properly, they will be an asset for a long time and not just an expense that keeps recurring. Are you prepared to boost the performance and reliability of your industrial shearing machine? Select Unick Spring Pads and get rid of vibrations, increase the life of your machines, and boost the efficiency of your operations. Get in touch with Unick Vibration now and receive professional help, tailor-made solutions, and the right spring pad for your particular industrial requirements. Make a better investment. Have smoother operations. Get better performance with Unick.

How Unick Wedge Mounts Work to Isolate Vibration for Surface Grinders

Among the machines that grinding operations make use of, the surface grinding machines are the most common and at the same time the most sensitive to vibrations, even the slightest one could lead to the production of nonconforming parts. Unick Vibration Wedge Mounts are made to overcome these difficulties; they offer a strong vibration-free and stable base. As a result, manufacturers can reach an unrivalled level of precision, extend the life of the machine, and provide a constant quality of production. In this write-up, we shall look at the working principle of the wedge mounts, their main elements, advantages, and some guidance on how to select the correct one for your situation. Understanding the Mechanics of Wedge Mounts in Surface Grinding Machines Surface grinders depend on the very accurate positioning of workpiece to the grinding wheel. But vibrations coming from the motor of the machine, external sources, or the floor not being even can all lead to reduced grinding quality. This is where the wedge mounts come in. They can kill the vibrations and conduct the process of grinding smoothly and consistently. Wedge mounts operate through establishing a flexible but steady interface between the machine base and floor. So, rather than having the vibration’s energy transfer into the machine’s structure, the energy is absorbed. Thus, the chatter that is not wanted is prevented, the noise is reduced, and the tolerances are kept precise. Consider These Main Points: How Unick Vibration Wedge Mounts Provide Superior Vibration Isolation Unick Vibration’s Wedge Mounts and Anti Vibration Heighten Mounts are specifically designed to provide top-notch vibration isolation. Additionally, they have a design that is both durable and elastic to ensure maximum stability in grinding operations. In contrast to traditional mounts, the Unick wedges give you the benefit of multi-directional isolation which means that they can tackle vibrations caused by both horizontal and vertical forces. The unique features of the product are as follows: As a result, manufacturers get better quality surface finishes, fewer machine adjustments, and lower production errors. Key Components That Make Wedge Mounts Effective for Precision Grinding The efficiency of Unick wedge mounts is due to many key factors. First of all, to know these factors is to understand the reason for the superiority of the conventional isolation methods over these. Moreover, the installation also plays a role in the realization of the maximum benefits Core Components Include: To sum up, the mentioned parts are perfectly integrated and that they do not negatively affect the positive quality of the grinding Benefits of Using Wedge Mounts for Stability and Accuracy in Surface Grinders Unick wedge mounts and Anti Vibration Sandwich Mounts are not only reliable but also give you the chance to gain plenty of operational advantages. Let’s list some of them: they cut down on errors due to vibrations, they save damage to expensive machinery, and, last but not least, the positive effects can be felt in the whole area of production efficiency beside precision grinding. Major Benefits are as follows: Finally, all these benefits come to the point of cost savings, superior product quality, and reliable operational performance. Choosing the Right Wedge Mounts for Optimized Grinding Performance It is necessary to take a good look at machine specifications, operating conditions, and the level of isolation to be achieved before selecting the adequate wedge mounts. Thus, finding the right mount will allow it to work at its best and provide the user with long-term benefits. Points to Take into Account are: Moreover, consulting with vibration control specialists or Unick experts can lead to grinding operations being provided with customized solutions. Conclusion To summarize, Unick Vibration Wedge Mounts play a vital role in maintaining the highest precision and stability in surface grinding machines. The incorporation of state-of-the-art damping materials, precision engineering, and versatile designs in these mounts contributes to preventing the occurrence of vibrations, protecting the machines, and enhancing the quality of production. Consequently, manufacturers gain the benefits of uninterrupted operations, less maintenance, and improved surface finishes. The purchase of top-notch wedge mounts is not a matter of choice anymore but rather, it has become a strategic move for the user to maximize productivity, safeguard the equipment, and stay ahead of the competition in precision manufacturing. Enhance the performance of your surface grinder now! Find out about Unick Vibration Wedge Mounts and take advantage of their unparalleled vibration isolation for fine grinding. Get in touch with us at Unick Vibration Solutions or ring +91 9718575974 to talk about tailor-made solutions for your equipment

How Unick Wedge Mounts Extend the Life of Your Turret Punch Machine in India

In India, the manufacturing sector today is very competitive and the turret punch machines are of utmost importance in sheet metal working, producing automotive parts, and engineering components with precision. On the other hand, as a result of constant use and fast punching plus the heavy workloads, these machines often experience vibrations, misalignment and short life spans. Consequently, the production rate goes down, maintenance costs go up, and the life of the machine is reduced. However, Unick’s Vibration’s wedge mounts are a way to solve these problems easily. They are made to last, be precise, and absorb the vibration among other things. Therefore, they are perfect to stabilize, wear down and enable the turret punch machine to work at its best. The article will cover the advantages of Unick wedge mounts and the reason for their being indispensable in the manufacturing units of India. Understanding the Role of Wedge Mounts in Turret Punch Machine Stability A turret punch machine when in operation creates a lot of dynamic forces. If there are no proper supports, these forces will be directly transmitted to the frame and the foundation of the machine, leading to vibrations and stress on the structure. Wedge mounts serve the purpose of being a barrier of utmost importance between the machine and the ground, thus the operation gets stabilized and the stress becomes less concentrated. Key Functions of Wedge Mounts To sum up, wedge mounts are a must-have item for maintaining the stability of the machining process, reducing the stress on the machine and, thereby, supporting the efficiency of the operation in the long run. How Unick Vibration’s Wedge Mounts Reduce Wear and Tear in Industrial Machines The Indian manufacturing units have to deal with high utilization rates, long working hours, and other difficult working conditions most of the time. This is the reason why the machinery and the equipment, having been designed and engineered for these challenging conditions must always be working at their best for Heavy Duty Anti Vibration Pads. Unick Vibration, therefore, specializes in designing wedge mounts specifically for such difficult situations where strong elastomer materials are combined with precision-engineered metal components. The Effectiveness of Unick Wedge Mounts In this way, Unick wedge mounts make significant contributions to the reduction of mechanical stress, prevention of frequent breakdowns, and extension of the machine’s service life. Improved Accuracy and Reduced Vibrations: Key Benefits for Turret Punch Machines Precision is highly needed in turret punching operations. Even tiny vibrations can cause improper holes alignment, tool damaging, and wastage of materials. The implementation of Unick wedge mounts brings about stability and precision, which in turn improves the performance of the whole machine. How Wedge Mounts Improve Accuracy Hence, manufacturers reap the benefits of improved product quality, decrease in rejection rates, and scrap reduction. Why Indian Manufacturing Units Prefer Heavy-Duty Wedge Mounts for Longevity In the case of Indian industrial environments, prolonged running time, heavy loads, and the unreliable power supply are common occurrences. Thus, the durability and reliability of the equipment are the prime concerns. Heavy-duty wedge mounts and Anti Vibration Heighten Mounts are the typical choice as they can handle such harsh conditions. Benefits of Heavy-Duty Wedge Mounts So, heavy-duty wedge mounts are, therefore, a strategic investment for Indian manufacturers who are looking for long-term machine reliability. How Proper Mounting Enhances Productivity and Lowers Maintenance Costs Industrial units face one of their major challenges with machine downtime. Poor mounting is a root cause along with its associated consequences such as frequent maintenance, tool damage, and delay in production. Wedge mounts have given a solution to these problems through providing better machine stability and efficiency. Benefits of Higher Output and Cost-Saving Therefore, the expenditure made on wedge mounts of good quality will be reflected in the form of higher productivity and lower operational costs. Conclusion Turret punch machines play a vital role in Indian manufacturing, but the lack of vibration control and mounting will cause a reduction in their performance and lifespan. Unick Vibration’s wedge mounts and Anti Vibration Stud Mounts are the answer, having been tested to provide better machine operation, less wear and more accuracy. Hence, they become a must in the extension of machine life, lowering costs, and increasing productivity. In the end, the decision of choosing high-quality wedge mounts would mean investing both in the reliability of the equipment and the excellence of manufacturing. Protect your turret punch machine today! Put your money on Unick Vibration’s heavy-duty wedge mounts and get better stability, less wear, and a machine that lasts longer. Get in touch with Unick Vibration right away to obtain professional guidance and pick the ideal wedge mounts for your manufacturing plant in India. Increase productivity, decrease downtime, and obtain long-lasting performance!