Key Features of Unick’s Vertical Moulding Machine for Durable Insulation Sheets

The Unick Vertical Moulding Machine changes the game in the insulation sheet production area with its state-of-the-art features that take the insulation’s life span, production rate, and precision, which is a great advantage for the companies that are making such sheets, allowing them to sell in a competitive market at construction and industrial applications. First of all, think about how the raw materials would be changed into strong and long-lasting insulation sheets that could resist the toughest conditions. Of course, it is the Unick machine that takes over this task with a great success and at the same time it is the machine that streamline the whole production process. It is the Unick machine that helps the manufacturer to excel in the area of quality and volume of production. Not only it does that but also the sheets it produces are outstanding in terms of durability. Heavy Duty Anti Vibration Pads manufacturers can rely on it for an effective and true-to-life service. 1. How Unick’s Vertical Moulding Machine Ensures Superior Durability in Insulation Sheets Find out how Unick’s avant-garde vertical layout and powerful architecture provide the insulation sheets with crazy tensile strength and wear resistance, which are, in fact, the most bisy among the highest high-rise buildings and the most extreme weather conditions. After that, the highly durable alloys inside the mould cavity will severely limit the possibility of corrosion. As a result, the sheets will be able to hold their quality for many years hence. In addition, the machine’s hydraulic system is capable of delivering incredibly accurate force (as much as 500 tons) that guarantees the formation of very dense molecular structures. Moreover, trials in actual conditions reveal Unick sheets to be 50% more resistant to abrasion than the rest competitors. Hence, companies can, with full confidence, provide longer product warranty periods. 2. Advanced Vibration Technology by Unick Vibration for Enhanced Sheet Strength The secret technology of Unick Vibration makes use of controlled vibrations that allow for the compaction of insulation sheets, and as a result, the strength and load capacity of the sheets are increased dramatically for the use in cars and planes. Further, the oscillation frequencies are from 50 Hz to 200 Hz and can be adjusted using a touchscreen. After that, this facilitates the sorting of the particles in a way that the sheets become 35% stronger in terms of compressive strength. The up to date Unick vibrators really work in perfect time with the machine cycle. Consequently, production is faster without the downside of quality. Also, the clients give feedback about the reduction of rejected products by 20%. As a result, this technology changes the standard of sheet’s reliability. 3. Precision Temperature Control for Consistent and High-Quality Moulding Results The latest thermocouples and PID controllers by Unick keep the temperatures exact, and so the molding of insulation sheets with uniform curing and few defects for premium quality output is done flawlessly. Temperature precision is a key factor next to vibration. To begin with, the zones heat independently to a maximum of 300°C. So, the gradients remain under 2°C throughout the mould. Then, the AI-based algorithms predict and regulate the heat flows. Hence, the curing is uniform. In addition, this eliminates hot spots that make the material brittle. In short, consistency reaches new heights and waste is reduced by 25%. 4. Energy-Efficient Design That Reduces Production Costs Without Compromising Output With engineering focused on sustainability, the machine of Unick is designed in such a way that it reduces energy consumption by 40% because of smart insulation and variable drives resulting in lower operating costs along with the efficient production of high-quality insulation sheets in large quantities. Switching to effectiveness, power savings come out as winners. To start with, the usage of servos takes over the hydraulics, which results in a 35% reduction in the total consumption. Moreover, the heat recovery system reuses the exhaust air. Afterwards, the establishment of idle modes lowers the standby power consumption by 60%. This, in turn, leads to a faster ROI. As a result, the company’s profits rise. 5. User-Friendly Operation and Automated Safety Features for Seamless Manufacturing User-friendly interfaces and AI safety measures render Unick’s equipment suitable for any user, regardless of the operator’s skill level; thus, automatic shutdowns and user-friendly designs guarantee safety and continuity in the production of long-lasting insulation sheets. So, at last, comfort and security combine. Initially, the 15-inch HMI provides intuitive guidance to the operators. Additionally, voice commands facilitate the setup process. Moreover, the system is equipped with sensors that can instantly detect any irregularities. Consequently, e-stops are activated with reliability. Conclusion Unick’s Vibration Moulding Machine symbolizes a new era in insulation production. Its features eventually result in the generation of sheets that are not only efficient but also long-lasting. Thus, it is suggested that you adopt it as a means to attain market leadership. Are you ready to boost the production of your insulation sheets? Get in touch with Unick now for a proficient demonstration and an expert quote! Check out https://unickvibration.com/ or dial +91 9718575974 right away.

Why Haryana’s Top Spring Manufacturers Choose Unick Levelling Pads

In Haryana’s rapidly advancing manufacturing industry, particularly with precision-oriented spring manufacturers, machine stability, vibration management, and precision are crucial factors. A very small amount of vibration can jeopardize the quality of the product, cause misalignment, and thus increase downtime. Hence, manufacturers prefer to have solutions that give both accuracy and reliability over time. This is exactly where Unick Levelling Pads come into the picture. The levelling pads that are specifically designed for rigorous SPM (Special Purpose Machine) operations guarantee precision, minimize wear and tear, and thus, upgrade the entire machine performance. This is why manufacturers from various industries in Haryana have come to rely on them for uninterrupted production and smooth workflow. How Vibration Wedge Mounts Enhance Precision and Stability in SPM Machines To achieve accurate and repeatable results, SPM machines need super stable foundations. A tiny imbalance or vibration can disrupt the machining tolerance, lead to a higher rejection rate, and inflict damage on the tool. The solutions to these problems that Unick’s vibration wedged mounts offer are a stable and shock-absorbing interface between machine and floor. Among the different ways they enhance stability and precision are: The Role of Unick Vibration Wedge Mounts in Reducing Downtime and Maintenance Costs One of the most expensive problems in manufacturing is downtime. Machines that have excessive vibrations are soon to go through all the above consequences; they wear out faster, break tools, and perform inconsistently. This explains why Unick Vibration’s wedge mount pad are widely used in the Haryana industry to safeguard their machinery. The vibration control mounts contribute to the following in terms of lessening downtime and maintenance: Why Haryana’s Manufacturing Units Prefer Advanced Anti-Vibration Solutions Modern production calls for high output, precision, and durability. Conventional mounts do not comply with these developing requirements. Thus, industries are turning to high-tech Heavy Duty Anti Vibration Pads solutions such as Unick wedge mounts. Reasons behind this preference include: Key Benefits of Installing Wedge Mounts for High-Performance SPM Operations SPM machines that run nonstop require stability as a must. Unick wedge mounts give the industries a variety of benefits together with performance, productivity, and safety. The most important benefits are: How Proper Machine Mounting Improves Productivity and Extends Equipment Life Mounting the machine is a very important factor that determines how efficient the manufacturing process will be. Also, correct anchoring and vibration absorption affect both output quality and machine lifespan. The effect of correct mounting is as follows: Conclusion In Haryana’s extremely competitive manufacturing environment, companies cannot make mistakes, suffer production downtimes, or use unreliable equipment. This is one reason why the supply of sophisticated mounting solutions for machines is ever-increasing. Unick Vibration Levelling Pad Supplier in India and Wedge Mounts have really come up as reliable and high-performing solutions that cater to the needs of the present industry. They are the reason why precision getting and securing maintenance costs are going down, machine life is getting extended, and production quality is becoming consistent; they are also the reasons why leading spring manufacturing units in Haryana prefer them. Ready to upgrade your SPM machine performance with industry-leading vibration control? Then don’t look further than Unick Vibration’s top-notch levelling pads and wedge mounts. Make your manufacturing process very stable, productive, and still of very high standards, starting today!

Why Every SPM Machine in Haryana Needs a Unick Wedge Mount

Special Purpose Machines (SPM) are run at very high speeds. They also continuously perform heavy-duty tasks in the factories. In Haryana, where automotive, fabrication, textile, packaging, and metalworking industries are the main ones, the demand for machine stability, precision, and long-term durability is a must. It is at this point that Unick Wedge Mounts become a necessary part of the high-performance operations. SPM machines are subjected to heavy vibrations caused by fast cycles, rigid tooling, and repetitive motion. These vibrations, along with the imbalance they cause, not only decrease the quality of the output but also drastically reduce the life of the machine. The application of a high-quality Unick Wedge Mount and Heavy Duty Anti Vibration Pads helps in countering these issues, delivering stability, noise reduction, and longer machine life. 1. How Vibration Wedge Mounts Improve SPM Machine Stability and Precision The SPM machines suffer from vibrations that sometimes result in misalignment, inaccuracies, and quickly worn-out tools. A Unick Vibration Wedge Mount acts as a stabilizer by absorbing and dampening the undesirable vibrations. In addition, it guarantees that every machine part is aligned precisely even when operating at high speed. How wedge mounts augment stability and precision: 2. The Role of Unick Vibration Technology in Enhancing Machine Lifespan The Unick Vibration Technology is a name that has always been associated with the top-notch quality of the vibration control solutions. In Haryana’s industrial ecosystem, where SPM machines run for extended periods, the longevity of the machines has a direct impact on ROIWays in which Unick Vibration Technology prolongs machine life: 3. Key Benefits of Using Wedge Mounts for Heavy-Duty SPM Machinery in Haryana Various industries in Haryana including automotive production, industrial tools, and steel manufacturing need SPM machines that are very strong. So, the installation of Unick wedge mounts and Levelling Pad becomes a vital strategy. The main advantages are: 4. Reducing Noise, Wear, and Downtime: Why Wedge Mounts Are Essential Noise and mechanical wear problems are faced by many facilities across Haryana. The installation of Unick Wedge Mounts is indeed a very efficient and instant solution to these problems The way wedge mounts cut down noise and wear: 5. How Unick Vibration Wedge Mounts Ensure Better Performance in Industrial Environments Dust, temperature changes, humidity, and heavy load operations are common in industrial plants located in Haryana. Unick wedge mounts and Anti Vibration Stud Mounts are made to survive all these conditions without any hassle. Performance advantages inside real-world industrial environments: Conclusion A Unick Vibration Wedge Mount is not an accessory but rather a critical necessity for every SPM machine working in Haryana. It increases machine stability, reduces noise, minimizes wear, and increases precision significantly while extending machine life. Besides, it also offers industries smoother operations, lower maintenance costs, higher productivity, and improved ROI.The PM machine is utilized in different industries like automotive component manufacturing, special machining processes, drilling, punching, forming, and metalworking, however, the performance and reliability in the long run of Unick’s vibration wedge mounts are always the same. Ready to enhance your SPM machine’s stability, accuracy, and lifespan? Experience the new, better performance by choosing Unick Wedge Mounts today. You can also reach out to Unick Vibration for the nearest supplier in Haryana for professional advice and help with the installation.

Best Unick Spring Pads Installation in India for the Clicker Machine

In the industrial sector where everything happens really fast, smooth processing and exact performance are the two things that can’t be forgone. Clicker machines, which are the industry-standard for leather, rubber, and plastics, mainly depend on their spring pads for maximum efficiency. Unick Spring Pads, which are among the most trusted products in India, have now become the preferred choice of manufacturers who need durability, vibration reduction, and reliable output. This paper tries to explain first the importance of professional installation of Anti Vibration Spring Pad, then discuss the procedure to be followed, and finally state the major advantages that ultimately make them necessary. Why Unick Spring Pads Are Essential for Smooth Clicker Machine Performance Machine Stress during Production, Clicker machines are subjected to immense mechanical stress when cutting the material. Proper selection of spring pads has a direct influence not only on the machine lifespan but also on the quality of the end product: Consequently, high-quality spring pads should not be seen as an option but rather a must for manufacturers who value operational excellence. Step-by-Step Guide to Professional Unick Spring Pads Installation in India The installation of Unick Spring Pads and Heavy Duty Anti Vibration Pads involves expertise, proper handling, and strict adherence to the manufacturer’s guidelines. Nevertheless, when implemented in a structured manner, it becomes the fountain of machine performance and longevity. Pre-Installation Inspection: Picking the Right Spring Pads: Disassembling the Machine: Installing the Pads: Testing After Installation: If you follow these procedures, you will get your clicker machine running perfectly and steadily with very little downtime. How Unick Vibration Technology Enhances Clicker Machine Stability Unick Spring Pads and Levelling Pad make use of state-of-the-art vibration-absorbing technology which is made specifically for industrial machines: Thus, the advanced spring pads are used along with, and the result is the substantial operational efficiency and safety. Top Benefits of Choosing Genuine Unick Spring Pads for Industrial Use The decision to use unadulterated Unick Spring Pads instead of the cheaper ones has a few but very important advantages for the industry to enjoy: Thus, the choice of spring pads and Rubber Pads from Unick is a well-thought-out investment not only in efficiency but also in quality of the products. Common Installation Mistakes to Avoid With Unick Spring Pads on Clicker Machines Even the best pads can break down if installation is not done properly. Hence, it is very important to know the mistakes that are often made: Manufacturers by avoiding these mistakes make sure that the Unick Spring Pads performance is optimal and they receive all the benefits from that. Conclusion The Conclusion is that the professional installation of Unick Spring Pads and Anti Vibration Elastomeric Pads is very important for any industrial setup that is depending on clicker machines. The pads bring not only machine stability and cutting precision but also a smoother maintenance process, which, in turn, leads to an increase in overall productivity. The benefits are from the cutting-edge vibration technology to the reliability of the variety of pads used. The Indian manufacturers aiming at the long-term operational effectiveness should put the professional installation in their priority list and also buy the original Unick Spring Pads. Give the performance of your clicker machine a boost by having the professional Unick Spring Pads installation done in India. Do not hesitate to contact Unick Vibration specialists immediately in order to make an appointment for your installation and thus to experience the unmatched precision, stability, and efficiency that only the authentic Unick products can give.

Why Every VMC Machine Owner in Haryana Should Consider Unick Insulation Sheets

VMC (Vertical Machining Centre) machines are the essential pillar of manufacturing activity in most of the Haryana workshops. The winning point of a workshop is the combination of precision, speed, and durability, and the quality of the output is affected by every little detail. Therefore, now more than ever, machine stability and vibration control are crucial. Unick Insulation Sheets come in as a revolutionary product that promises not just to facilitate the performance enhancement, but also to give a decrease in vibration, and to give to the protection of the expensive machinery. Through this article, you will learn about the phenomenal impact the Unick Insulation Sheets have on the VMC operations and the reasons for so many workshops in Haryana to depend on them for better quality of work. How Unick Insulation Sheets Enhance VMC Machine Stability and Productivity Each VMC machine is a source of heat and vibration during the process of operation. Gradually, these two forces lead to the mechanical stress, the precision loss, and the production cycles being drawn out. This is exactly the reason for which it is suggested that the use of the Unick Insulation Sheets should be installed, in order to bring about a significant difference. The Unick Insulation Sheets, created by Unick Vibration Solutions, serve as a physical and thermal barrier under the hulk VMC machines. Besides that, they are doing the job of vibrations absorption and eliminating the micro-movements responsible for misalignments. The outcome of these actions is that machining is becoming smoother, surface finishes are becoming consistent, and cutting performance is precise throughout the long production runs. This is how Unick Insulation Sheets are adding value to the daily operations: In addition for Heavy Duty Anti Vibration Pads, Unick Insulation Sheets have a positive impact on the lifespan of the VMC foundation and important parts since they have less application of stress on the joints, bearings, and mounting points. Why Haryana’s VMC Workshops Prefer Premium-Grade Insulation for Long-Term Efficiency Haryana’s industrial zones, especially in Sonipat and Kundli, are not only great for the manufacture of automotive parts but also plastics, moulds and precision engineering. Quality has always been the main criterion for workshop owners, and thus investing in vibration isolation of premium grade is considered to be a necessity in operational terms rather than direct cost. On the other hand, when it comes to dependability, Unick Insulation Sheets have been able to make a good name for themselves by offering nothing but consistent performance. The key ingredient in making those sheets or using dense elastomeric compounds and reinforced designs is that they cater to the heaviest VMC bases. Some of the main factors why workshops in Haryana favour Unick insulation are as follows: Thus, a lot of VMC machine owners experience a decrease in reworks, a reduction in downtime, and an increase in energy efficiency after the installation of Unick Sheets. The Role of Unick Vibration Solutions in Reducing Downtime and Machine Wear Downtime does not only cost but also the machine industry in Haryana is so competitive that the one who has the most productivity will always win. Unick Vibration company understands this difficulty and helps the customers with state-of-the-art insulation and damping materials. Unick Insulation Sheets and Anti Vibration Cushy Foot are not only made from generic rubber or ordinary foam but they are specially designed based on thorough analysis of vibrations and loading. The manufacturer utilizes its knowledge in controlling dynamic vibrations and in doing so provide insulation sheets for use in industry. And this leads to: In other words, every hour not spent on maintenance or downtime is directly converted into higher returns, and that is exactly what Unick solutions offer. Top Benefits of Using High-Density Insulation Sheets in CNC & VMC Operations For machine owners who want the best of both worlds, Unick’s insulation sheets of high density offer a significant advantage. They incorporate many benefits that exceed the need for noise control. Such benefits are: In addition, Unick Insulation Sheets are created with the expectation of having a long lifespan, which means fewer replacements and less discarded materials resulting in a more sustainable and cost-effective operation. How Better Heat and Vibration Control Improves Your VMC Machine’s Lifespan The lifespan of a VMC machine is highly dependent on the maintenance of internal alignment and vibration-free cutting. If vibrations are too high, not only will quality be low but also the life of mechanical joints, bearings, and electrical systems will be reduced. With Unick Insulation Sheets: In addition, the system remains cooler, quieter, and more reliable as a result of managing thermal expansion and preventing energy loss through vibration. This means that there will be fewer unplanned repairs and longer service life. The climate in Haryana, particularly its high summer temperatures, creates thermal stress for industrial equipment. Unick’s insulation design reduces the temperature variations that usually cause distortions in the machine bodies, thus guaranteeing the precision is maintained throughout the year. Conclusion In Haryana’s thriving industrial sector, efficiency, and precision stand out as the factors that determine market leadership. The VMC machine owners that decide to upgrade to Unick Insulation Sheets will experience better stability, noise reduction, accuracy improvement, and longer equipment life. The initial investment is quickly recouped through increased production and lower maintenance costs. A small die shop or a large CNC workshop, whichever you may operate, the selection of Unick Vibration Solutions guarantees that the foundation of every machine will work as hard and as smart as your production team. With the Unick Insulation Sheets, the trusted solution for vibration-free, heat-resistant, and precision-driven machining, you can upgrade your VMC machine’s foundation today. Get in touch with Unick Vibration Solutions right away to receive professional advice, installation support at no cost, and recommendations for products that are suitable for the layout of your factory.

A Complete Guide to Installing Pressure Die Casting Machines on Unick Wedge Mounts

The setting up of a pressure die casting machine needs accuracy, alignment, and firmness of the structure. In addition, selecting the proper mounting system is important in Heavy Duty Anti Vibration Pads and machine performance over time. In this article, we will discuss how Unick Wedge Mounts not only make the installation process easier but also provide the highest stability for the heavy-duty die-casting machines. 1. Understanding Pressure Die Casting Machines and Their Installation Requirements The industry nowadays greatly depends on pressure die casting machines, as they manufacture high-precision metal parts, mainly for automotive, aerospace, and electrical equipment industries. These machines apply such high pressures that the molten metal is quickly injected into the dies forming complex parts with excellent dimensional accuracy. On the contrary, if installed improperly, it can give rise to alignment problems, unequal pressure distribution, and machine wear. Thus, the application of a solid and controlled foundation becomes indispensable for consistent operation. Main Installation Demands: A proper foundation, which is flat and with controlled vibrations, to stop movement in the case of machines. In other words, prior to the execution of any alignment or installation, knowledge of the forces interacting helps to choose the right vibration mount system and that is the time when Unick Wedge Mount Pads come into the picture. 2. What Are Unick Wedge Mounts? Key Features and Engineering Benefits Unick Wedge Mounts are durable industrial-grade anti-vibration and leveling systems for machines like VMCs, CNC tools, and die-casting setups. Unlike the traditional grouting system for foundations, Unick mounts are different because they give mechanical strength and at the same time isolate vibrations. Furthermore, these mounts come with wedges that give exact levelling even when there are heavy static and dynamic loads. The Unick Wedge Mounts’ Core Features: The benefits from engineering include: Thus, Unick Wedge Mounts and Anti Vibration Stud Mounts reverse the conventional die casting installation method into an up-to-date, flexible and silent system. 3. Step-by-Step Guide to Mounting Die Casting Machines on Unick Wedge Systems Putting your pressure die casting machine on Unick Wedge Mounts is simple but at the same time needs a systematic approach for the best results. The setup process can be a tad tricky, but if you follow the steps below, you will not suffer a loss due to accidents or incorrect settings. Step 1: Foundation Preparation Step 2: Placement of Wedge Mounts Step 3: Lowering the Machine Step 4: Levelling Process Step 5: Tightening and Vibration Check Step 6: Final Inspection Therefore, correct installation becomes a factor that assures the die casting machine of precision and operational smoothness over a long time. 4. How Unick Vibration Solutions Improve Stability During Machine Installation The wedge mounting technology from Unick involves the use of state-of-the-art vibration engineering principles. This, in turn, not only increases the precision of the installation but also prevents the entire system from suffering too much mechanical stress. Unick Vibration technology provides the following benefits to pressure die casting setups: In addition to this, reduced noise and vibrations lead to longer life for the machine as its parts like bearings, joints, and frames are less stressed. Moreover, Unick’s mounts are put through tests to ensure that they work great under all kinds of load, so the die casting machine is always supported even when it’s running at its highest capacity. 5. Safety Checks and Maintenance Tips After Installing on Unick Wedge Mounts Periodic safety checks are important even when using dependable systems such as Unick Wedge Mounts. Therefore, if inspections are performed timely, the machine will be safe and have a long performance life. Regular Safety and Maintenance Tips: Moreover, the maintenance log that is kept can be a good way to let the technicians know how the mounts are performing and what kind of preventive care they need. So, continuous surveillance is necessary to ensure not only safety but also the precision of your die casting machines. Conclusion Putting up pressure die casting machines equipped with Unick Wedge Mounts is not merely a temporary task of installation but an engineering upgrade in the direction of exactness, efficiency, and durability. The wedge mechanism grants a firm ground, the best vibration handling, and the quickest alignment, all leading to the maximum output of the machine. In short, Unick Wedge Mounts change the old ways of installation with a more intelligent, powerful, and easy-to-maintain design, thus being the most suitable base for your top-notch die casting project. So, do you want to make your pressure die casting machines more stable and accurate? Visit https://unickvibration.com or call +91 9718575974 to discover the transformative impact of Unick Wedge Mounts and anti-vibration technology on your plant’s productivity. Get in touch today, and witness engineering that always stays strong.

Reduce Machine Downtime: The Role of Unick Spring Pads in Paper Roll Production

A slight vibration, an imbalance, or a misalignment can, in the competitive world of paper roll manufacturing, bring along production problems of a large scale. The stoppage of machines not only slows down the output but also directly raises the operating costs, affects the accuracy of the product and then adds up to the overall loss of profitability. This is the very reason why the industries have today turned towards advanced Heavy Duty Anti Vibration Pads solutions very quickly. Among them, Unick Spring Pads have been one of the most trusted parts for achieving stability, precision, and longevity in the machine.Not only that, but they also play a very important part in keeping the whole process running smoothly even through heavy-duty, high-speed production cycles. How Unick Spring Pads Minimize Vibrations and Prevent Costly Production Halts3 Vibration is one of the major concealed foes of paper roll production. If the machines are running at high speeds, even a minor instability can cause a series of failures. Unick Spring Pads are specially made to absorb shock, decrease vibration transmission, and keep machine alignment. How They Help Reduce Downtime Why It Matters Paper roll production is dependent on a machine rhythm which is constant. A moment of disruption and the whole workflow is affected. Thus, controlling vibration is the same as reducing breakdowns, production delays, and getting smoother operations. Unick Spring Pads are the ones who have the deck; they are the ones who guarantee that all parts of the machine operate in the same way. Boosting Paper Roll Precision: Why Stable Machine Operation Matters Precision is a major issue indicator in the paper industry daintily pipelines. Mismatched paper rolls, varying thickness, or displaced layers cause material to be wasted to a large extent and customers unhappily so. Stable machine operation ensures that: However, when stability is compromised, the roller mechanisms encounter increased friction which results in product defects. This is where Unick Spring Pads present their unmatched worth. Unick Vibration Technology: Enhancing Machine Safety and Reducing Wear & Tear Unick’s technology for controlling vibration has been specifically designed, with a focus on long-term machinery safety, to offer such a benefit. The Spring Pads and Insulation Sheets created by them comprise of top-tier elastomers and springs that not only magnify load bearing capacity, but also facilitate shock absorption. Key Contributions to Machine Safety: Machine wear and tear somehow cause misalignment, loosened bolts, and even abrupt failures. Nevertheless, put the right vibration-control system in place, and such risks are immensely reduced. Unick Spring Pads are the ones that help machines to have longer lives and stay healthier, as well as extending the operational life and improving safety parameters. Key Advantages of Using Spring Pads in High-Speed Paper Roll Manufacturing Production lines that run at high speed need parts that can tolerate constant stress. Unick Spring Pads and Levelling Pad play a significant part by remaining robust even in the most challenging places. The list of major benefits includes: In addition to that, they also balance out the operation, thus maintaining the same output. The manufacturers will have a reliable product at their disposal along with Unick Spring Pads that will guarantee every production run is of the same high standards in terms of speed, precision, and efficiency. Increasing Output Efficiency Through Better Shock Absorption and Load Management The machinery that rolls paper is subject to extreme pressure and tireless load cycles. Obviously, the machines to which the shock absorption technique is not advanced face jolts, imbalances, and friction-related damage. However, Unick Spring Pads are there to take on these problems and to make load management optimum. What this means in terms of efficiency: Anti Vibration Stud Mounts Management of consistent loads gives machines maximum efficiency without the risk of overheating or loss of accuracy. Meanwhile, the smoother production line minimizes interruptions and better energy utilization which, in turn, contributes to a more cost-effective operation. Conclusion Unick Spring Pads are no longer seen as accessories; they are now indispensable parts of the modern paper roll manufacturing unit. By significantly lowering the vibration levels, softening the impact, and efficiently handling the heavy loads, and providing the required precision, they become the ideal choice of the industries in search of long-term performance and reliability. As a result, the businesses which want less period of inactivity of machines and highest production rate should apply Unick Spring Pads in their machines. The end result will be that with more stability the business will have better quality, more output, and more profit. Make your production line modern with Unick Spring Pads now! Machines working under the best conditions, the safest way, and the smoothest way, without unexpected breakdowns or expensive downtime. Our team is ready contact you for advanced vibration-control solutions and premium-quality Unick Spring Pads. Stability is increased, accuracy is improved, and the paper roll production is taken to the next level.

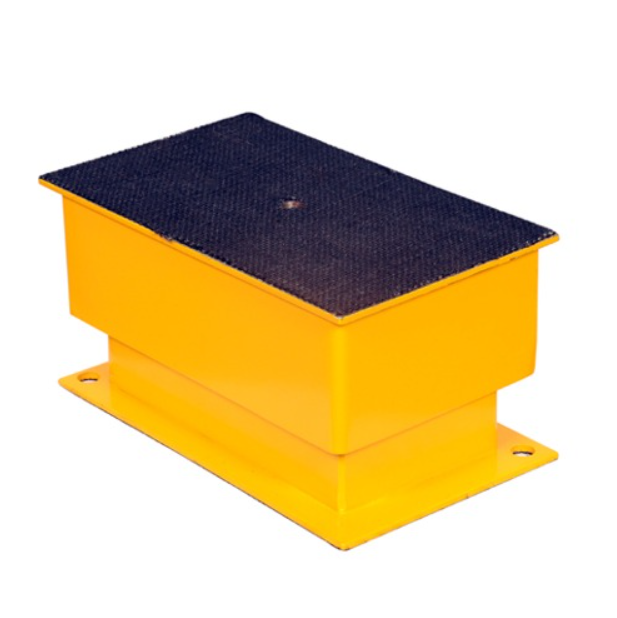

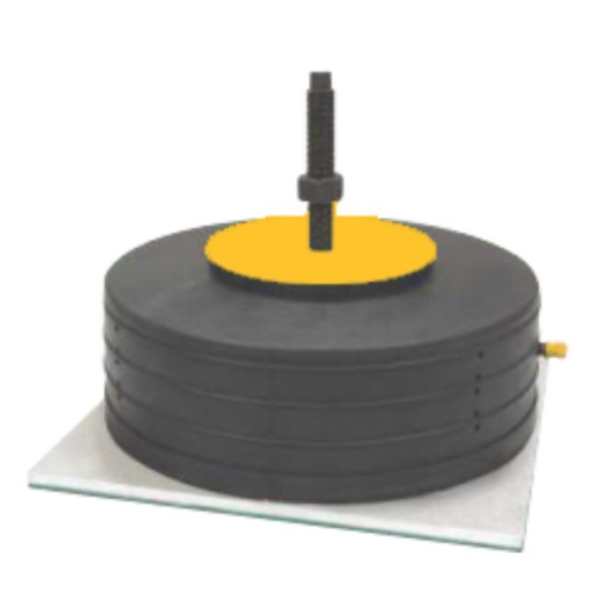

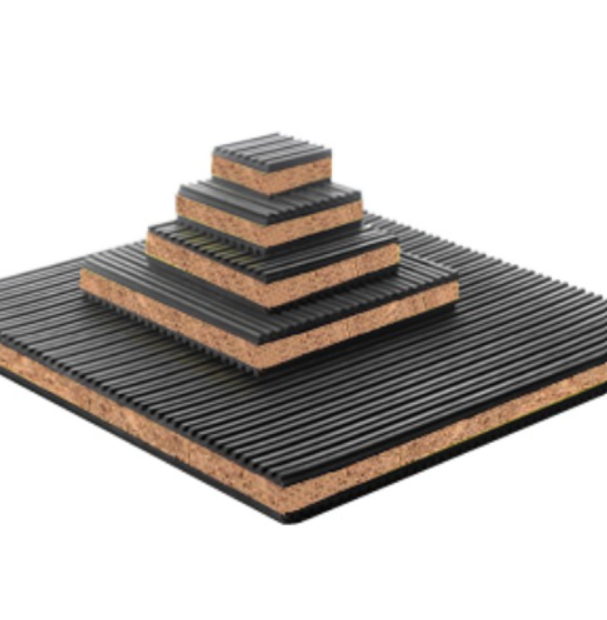

Best Anti Vibration Pads for CNC Machines India

CNC machines are known for precision and productivity, but high-speed operations often lead to excessive vibration. This is where Anti Vibration Pads for CNC Machines play a crucial role, ensuring stability, accuracy, and longer machine life. If you are searching for the best anti vibration pads for CNC machines in India, this guide from Unick Vibration will help you understand what they are, how they work, and how to choose the right ones for your CNC setup. What Are Anti Vibration Pads for CNC Machines? Anti vibration pads are specially engineered pads designed to absorb and reduce vibrations produced by CNC machines. They minimize oscillation, protect machines from wear, and stabilize machine performance. These pads are made from high-quality rubber, nitrile, cork, or composite materials to ensure strong grip, effective vibration absorption, and long operational life. Why CNC Machines Need Anti Vibration Pads India? CNC machines work with high-speed spindles, rapid cutting movements, and continuous operational loads. These forces create vibrations that directly affect machining accuracy, surface finish, and machine health. Anti Vibration Pads help control these unwanted vibrations, ensuring smoother performance and longer machine life. Here’s how they make a difference: Types of Anti Vibration Pads for CNC Machines Different CNC machines require different vibration control solutions. At Unick Vibration, the following are the most preferred anti vibration pad types designed specifically for CNC Machines, CNC Engraving Machines, CNC Lathe Machines, and CNC Turning Centers. Anti Vibration Spring Pads – Best for CNC Machines Anti Vibration Spring Pads are ideal for heavy CNC Machines that operate at high speeds and generate strong vibrations. These pads use high-strength steel springs combined with rubber elements to absorb vibration energy and stabilize machine performance. They are perfect for CNC mills, VMCs, HMCs, and large machining centers where precision is critical. Features: Types: Anti Vibration Wedge Mounts Pads For CNC Turning Machine Anti Vibration Wedge Mount Pads for CNC Machine are designed to provide excellent leveling and vibration control for medium to heavy CNC setups. Unick Wedge Mount Pads use an advanced wedge mechanism that allows precise height adjustment and machine alignment without requiring any floor anchoring. They are perfect for CNC Turning Machines, milling machines, engraving machines, and high-speed CNC operations where stability and accuracy are essential. Features: Types: Anti Vibration Levelling Mounts Pads Levelling Mount Pads are ideal for CNC machines that require accurate balancing and height alignment. These mounts combine anti vibration rubber bases with a leveling screw, ensuring the machine remains perfectly stable even during high-speed operations. They are best suited for routers, turning centers, VMCs, and cutting machines. Features: Types: Anti Vibration Heighten Levelling Mounts Pads For CNC Machines Heighten Levelling Mount Pads offer both vibration absorption and extended adjustable height range. These mounts are perfect for CNC machines that need additional ground clearance for maintenance, chip removal, coolant flow, or conveyor integration. They provide stability, height control, and vibration reduction in one solution. Features: Types: How Anti Vibration Pads Work Anti vibration pads use a combination of material density, elasticity, and friction to absorb vibration energy. When placed under the CNC machine’s feet: This simple yet powerful mechanism makes them essential for all CNC environments. Benefits of Using Unick Anti Vibration Pads When choosing pads in India, you want a brand known for quality, durability, and performance. Unick Vibration offers industry-grade pads designed especially for CNC applications. Key Benefits: Unick Vibration products are trusted by machine shops, manufacturing units, automotive companies, industrial workshops, and CNC automation experts across India. How to Choose the Best Anti Vibration Pads for Your CNC Machine Before purchasing, check the following: 1. Machine Weight: Always select pads that can support the complete weight of your CNC unit. 2. Type of CNC Machine: Different machines like VMC, HMC, Turning Centers, and Routers have unique vibration levels. 3. Floor Type: Check if your factory floor is concrete, tiled, epoxy-coated, or uneven. 4. Vibration Frequency: High-speed CNCs require pads with higher vibration absorption capacity. 5. Environmental Conditions: Consider oil, coolant, heat, and humidity levels in your workshop. 6. Brand Quality & Warranty: Choose reputed brands like Unick Vibration that offer long-lasting and reliable pads. Installation Tips for Anti Vibration Pads Installing CNC anti vibration pads is quick and simple: Proper installation enhances machine stability and reduces vibration significantly Why Unick Vibration Is the Best Choice in India Unick Vibration is a trusted name in CNC anti vibration solutions. With decades of experience and high-quality engineering, we ensure: Our pads are designed to deliver the best vibration isolation performance for CNC machines in India, helping factories improve productivity, accuracy, and operational efficiency. Conclusion Choosing the right Anti Vibration Pads for CNC Machines is essential for smooth machine operation, better precision, and longer machine life. Whether you own a small workshop or a large manufacturing plant, high-quality anti vibration pads from Unick Vibration can significantly improve your CNC performance. If you are looking for the best anti vibration pads for CNC machines in India, Unick Vibration is your trusted partner. Upgrade your CNC setup today with reliable, durable, and performance-driven vibration control solutions.

Why Indian Factories Are Switching to Unick AVM Pads for Mezzanine Floor Machinery

Indian industries are quickly changing and bringing up-mezzanine floors as an inevitable addition among the most common factories of today’s structural innovations, owing to space limitations and operations expansion. Yet, positioning heavy machinery on these high platforms could lead to some issues, such as: vibration, noise, reduced stability, and structural wear. This is where the Unick AVM Pads get to the necessary level and thus become a solution that has positively affected the industry. Factories in India are increasingly and steadily adopting the Unick Heavy Duty Anti Vibration Pads for excellent vibration control, long-term durability, and operational safety. In addition, with productivity and machine durability becoming the key considerations, the industries are going for the advanced anti-vibration solutions that truly affect the situation. How Unick AVM Pads Reduce Machinery Vibration on Mezzanine Floors Unick AVM Pads are designed with the sole purpose of overcoming the severe vibration problems that occur with the big machines placed on the mezzanine floors. These high-level surfaces usually intensify the vibrations which results in: Unick AVM Pads work by taking advantage of advanced elastomeric materials and a multi-layer design to minimize these problems in a very clever and efficient way. Key Points of Their Vibration Reduction: In addition, when the machines are located at the mezzanine, even the smallest vibration can be transmitted very fast. Unick AVM Pads and Insulation Sheets stop this transmission thus making the area around the machine stable and safe. The Science Behind Unick AVM Pads: Better Stability, Less Noise Unick built their AVM Pads using a science-based technique which is in isolation of vibration, distribution of load, and behaviour of the elastomer under pressure. How the Technology Works: The Ingenious Application of This Science-Driven Engineering: Unick AVM Pads and Levelling Pad serve as a barrier that is simple yet highly effective between the machinery and the mezzanine floor structure. Why Indian Industries Prefer Unick Vibration Solutions for High-Load Equipment Factories in India, encompassing the automotive, manufacturing, and packaging industries are starting to trust Unick Vibration solutions more and more. Their AVM Pads have been, so far, tested in a variety of industrial settings and have been found to be effective even with heavy-duty, high-load equipment placed on mezzanine floors. Most Important Reasons for Their Preference: Thus, the industries that are looking for a long-term and safe solution are shifting towards Unick AVM Pads. Cost Savings and Long-Term Durability with Unick AVM Pads The transition to Unick AVM Pads and Anti Vibration Stud Mounts is not only a technical upgrade but also a cost-saving measure. Often, stacking on mezzanine floors requires maintenance for the prevention of stress on the structure. The pads of Unick not only minimize this cost but do so consistently and significantly. Ways in Which They Assist in Cost Reduction The importance of durability The Unick AVM pads are highly durable. Their reliability is due to their ability to endure: Thus, the manufacturing unit has less replacements, more returns, and performance that is consistent throughout the life of the machine. Real-World Benefits: Improved Safety and Performance in Mezzanine Floor Operations In case of very heavy machinery, installing it on the mezzanine floor without proper anti-vibration solutions would not only endanger the machine but also the whole building. Unick AVM pads and Anti Vibration Sandwich Mounts prevent these risks from happening and deal with them when they occur. All the Real-World Plus Points: In the end, the complete operational environment becomes one that is safer, quieter, and much more productive. Conclusion Indian factories today are not thinking of vibration control as an investment that is optional; it has turned into a must-have especially for machinery on the mezzanine floor. Unick AVM pads and Rubber Pads offer engineering that is advanced, lastingness, and performance that is better than the traditional anti-vibration solutions. Besides, the increasing use of heavy machines on higher structures leads to industries emphasizing safety, stability, cost efficiency, and long-term reliability, all of which Unick AVM pads do excellently. To Your Factory, The Best Anti-Vibration Solution Today! Unick AVM pads will make your mezzanine floor machinery more stable, safer, and durable. Contact Now for Expert Guidance & Bulk Orders! Your factory is entitled to an impedance-free performance of the highest quality. Select Unick now!

Step-by-Step: Installing a Lathe Machine on Unick Levelling Pads

The installation of a lathe machine might be just another job to do in the workshop, but if you want to keep punching out perfect parts like clockwork, it will need proper planning, perfect alignment, and a good levelling system. Unick Levelling Pads are made to keep the lathe in place, eliminating vibrations, and ensuring that the lathe is accurate for many years. Besides that, they will save the machine owners from the high costs of misalignment that are caused by uneven concrete shop floors. This tutorial will guide you through the process of floor preparation, lathe alignment, Unick Levelling Pads mounting, and final precision checks in order to ensure that the machine performs exceptionally well. Preparing Your Workshop Floor for a Safe Lathe Installation Good installation is always built upon good foundation. Prior to installing the lathe, you need to make sure that your workshop floor is strong enough and thick enough to bear the load and to endure the vibrations from the machine while it is operating. What is more, floor preparation will lead to no structural damage in the long run, will make the working conditions safer for the operator, and will keep the calibration stable. Lathe machines are a source of massive vibrations, and as such, they depend on a very strong surface. If the foundation is not good enough, there might be tiny movements, which would affect the accuracy of the machining. Hence, preparing your floor is the very first thing to do. Steps to Prepare the Floor: Also, once the floor is ready, you set up a favorable condition for the levelling pad installation to be carried out successfully. How to Position and Align Your Lathe Machine Correctly Correct positioning guarantees precision in machining. A misaligned machine would mean that inconsistent cuts would be taking place, and hence faster tool wear, and errors due to vibrations would be even more frequent. Thus, aligning the machine beforehand not only increases accuracy but also prevents disasters from mechanical parts. The lathe needs to be in its appointed place and aligned with the naked eye before the levelling pads are laid down. Nevertheless, the last touch on the alignment will occur after the heavy duty anti vibration pads are put in place. Lathe Positioning Steps: Furthermore, always keep a safe distance from other heavy machines so that there will be no interference from vibration. Placing and Adjusting Unick Levelling Pads for Maximum Stability Unick Levelling Pads and Insulation Sheets are specifically developed to provide durable support and to suppress vibration, hence they are a must for accuracy to be preserved. In addition, they free up time and resources for grouting, thus making the whole process of installation cleaner and more efficient. The setup of these pads guarantees that the entire lathe is supported evenly. Among others, the feature of adjusting lets you fix the issue of an uneven floor without the need for restructuring. Installing and Adjusting the Pads: So, Unick Levelling Pads make it possible for you to have a perfectly balanced machine even if the floor is uneven. Why Unick Vibration Levelling Pads Improve Machine Accuracy Unick Vibration’s Levelling Pads and Rubber Pads are to a great extent a very good choice for lathe machine owners who consider very much the precision and the longevity of the tool. On top of that, they are skillfully crafted to insulate the vibrations from the machines, hence boosting the quality of the machining. Flooring is one of the main transmission channels of lathes’ vibrations, which may cause unintentional errors. However, Unick Vibration Pads not only absorb these inconveniences but also block any external vibrations from reaching the machine. Advantages of Employing Unick Vibration Levelling Pads: All in all, the use of these pads results in a more stable machining environment, which means consistent performance. Final Checks: Ensuring Precision, Balance, and Long-Term Performance The last stage is verifying the stability and performance of your machine after it has been placed and levelled. Finally, these checks ensure the installation is perfect before the lathe is fully operational. Even when using Unick Levelling Pads, a meticulous inspection guarantees that the lathe is still stable during the operation with the load applied. Things to Look for Before Starting the Machine: If after all this, slight adjustments are needed, Unick Levelling Pads make it possible to perform swift corrections without the need to take apart the machine. Conclusion The installation of a lathe machine is not just about putting it on the workshop floor. It requires detailed planning, perfect alignment, and reliable levelling support. Unick Levelling Pads and Anti Vibration Engine Mount, and particularly Unick Vibration Pads, give the ultimate in stability, precision, and long-lasting performance. To sum it up, applying these meticulous procedures guarantees that your machine not only operates smoothly, produces accurate outputs but also retains its reliability over an extended period. Do you want to set up your lathe machine with maximum accuracy and stability for a long time? Then, Unick Levelling Pads are the first choice for the best performance and vibration control. So, contact us today to get professional installation help and the best Unick machine levelling solutions!