How Unick Wedge Mounts Prevent Vibration Damage in Die Casting Machines

Machines for die casting operate at extremely high pressure and have very rapid cycle times, which makes them prone to extremely high vibrations, misalignment, and structural fatigue. Even slight vibrations can have a negative impact not only on the product quality but also on machine life and maintenance downtime. Unick Wedge Mounts have been designed specifically to prevent these issues by providing advanced heavy duty anti vibration pads, superior load stability, and long-term reliability. In addition to that, their design allows die casting plants to have more efficient operations with lower costs and higher safety standards. Understanding Vibration Challenges in Modern Die Casting Machines Modern die casting machines, whether cold chamber or hot chamber, work with strong injection forces and dynamic loads. Besides, high-speed cycles produce shock waves that go through the machine structure and the foundation. Vibrations are responsible for causing a variety of issues, which can be summarized as follows: Therefore, manufacturers are bound to spend on good quality vibration control techniques. How Unick Wedge Mounts Absorb Shock and Reduce Vibration Damage Unick Wedge Mount pads are made with precision levelling features and strong elastomeric elements that prevent vibration from travelling. Moreover, they also reduce structural resonance and take the machine’s efficiency up a notch. How They Work: Thus, die casting machines are now more stable, noise is less, and life of the operation is longer. The Science Behind Unick Vibration Control Technology in Industrial Machinery Unick’s vibration control technology is an excellent example of advanced engineering that can simultaneously act on dynamic and static forces. What’s more, research-backed innovations by Unick Vibration not only focus on delivering reliable motion control for levelling pads but also on coping even with the toughest industrial environments. Key Scientific Principles Used: In this way, machines are kept stable throughout the whole process, even when the loads are at their heaviest. Key Performance Benefits of Using Wedge Mounts in High-Pressure Die Casting Massive impact forces are exerted by high-pressure die casting machines during the injection process. As a result, ordinary mounts are unable to handle such extreme dynamic reactions. Unick Wedge Mounts and Anti vibration Stud Mounts provide several performance advantages that are unmatched: Major Benefits: Besides, these benefits reflect on production output and profitability directly. Why Manufacturers Prefer Unick Wedge Mounts for Long-Term Machine Stability Unick Wedge Mounts and Anti Vibration Sandwich Mounts are trusted by manufacturers from automotive, industrial, and foundry sectors for their consistent performance. The mounts not only contribute to the stability of the machine but also to the safety of the operations, the extension of asset lifespan, and so on. Reasons for Industry Preference: As a result, Unick Wedge Mounts have become the preferred choice of companies that want to increase productivity and reliability. Conclusion Die casting machines are subjected to extreme challenges of vibration due to their fast operations and large impact forces. But Unick Wedge Mounts and Rubber Pads offer an efficient, long-lasting, and scientifically designed way to reduce vibrations and improve performance of the machines. In the end, they enable the manufacturers to get the benefits of better production quality, more stable operations, and lower costs in the long run. The purchase of Unick Wedge Mounts is not merely a maintenance choice, rather it is a smart move to upgrade productivity. Today, Enhance Your Die Casting Stability! Are you after the machine’s long lifespan, low vibration, and smooth die casting process? Then, pick Unick Wedge Mounts for accuracy, toughness, and long-lasting reliability. Consultation by Experts Today – Your Machine is Worth the Best!

Protecting Your Induction Heater Investment: The Importance of Unick Rubber Air Spring Isolators

Induction heating systems are among the strongest and the most efficient technologies in modern manufacturing. They are also, however, delicate and highly sensitive to external forces such as vibration, shock, and noise. Moreover, if the forces that are not wanted are not managed, they can cause wear and tear before time, inaccurate heating results, and expensive maintenance. Hence, it becomes very important to choose the right vibration-control solution. This is exactly where Unick Rubber Air Spring Isolators come in, giving the best protection and allowing the industry not only to protect their costly induction heater installations but also to enjoy the stability of operations for a long time. 1. How Rubber Air Spring Isolators Safeguard Your Induction Heating Systems The rubber air spring isolators are specially designed to absorb and control vibration in places where machines are working very hard. Induction heaters have to be very careful in this aspect because they produce electromagnetic forces that can increase the level of vibration. Besides that, vibrations coming from heavy machines that are operating nearby can also affect the process negatively. Unick Rubber Air Spring Isolators give: Thus, your induction heater is left in a position of stability, accuracy, and also being immune to the long-term fatigue of the structure. 2. Enhancing Equipment Life and Performance with Unick Vibration Air Spring Solutions The air spring technology of Unick Vibration’s is meant for Heavy Duty Anti Vibration Pads only. One of the main requirements of induction heaters is precision; even a slight disturbance could render the whole heater uneven in the heating process. Moreover, vibration can easily shake up the inner parts, throw out of alignment the coils, and thus shorten the reliability of the system. To enhance the performance of the Unick Air Springs, the following is done: As a consequence, your induction heater is more efficient and retains its maximum performance for many years. 3. Key Benefits of Using Unick Rubber Air Spring Isolators for Industrial Applications Industrial users in search of isolators usually consider factors like durability, flexibility, and cost-effectiveness. Unick Rubber Air Spring Isolators meet all these requirements excellently. Besides, their superior material engineering guarantees that they can endure harsh conditions, fluctuating loads and long deployments. Among the most important advantages are: The machines are perfectly aligned and the operational stability is increased, thus the downtime is minimized. The end result is that there is a great reduction in the number of faults and the production of the factories is a lot smoother with Anti Vibration Stud Mounts. 4. Reducing Noise, Shock, and Vibrations to Protect High-Value Machinery Industrial places usually have a hard time with noise and vibration coming from the machines, especially in locations where the induction heaters are working close to the heavy manufacturing machines. The noise and vibration can be so excessive that they can even shorten the life of the control panels, coils, and power supply modules. The Coming together of Rubber Air Spring Isolators help the industry solve these issues of: Your factory workers get a better surrounding in terms of comfort and also the machinery does not get affected by the impact which is not required. 5. Why Modern Industries Prefer Rubber Air Spring Isolators Over Traditional Mounts Classic mounts like metal springs or rubber pads do not have the ability to meet the high speed industrial machinery’s advanced needs. Also, the traditional solutions could not provide exact damping at different frequencies, which is the case with technologies like induction heaters. Unick Rubber Air Spring Isolators are the preferred choice of modern industries because: Thus the Anti Vibration Spring Pads and ubber air spring isolators have earned being the favorite choice for the manufacturing plants, forging units, automotive industries, and electronic production facilities that want to be reliable vibration control. Conclusion Protecting your induction heating system is not only about performance; it is also about protecting a big financial commitment. Therefore, the use of top-notch vibration-control solutions such as Unick Rubber Air Spring Isolators guarantees that your machine will be accurate, efficient, and have a long life. In addition, these isolators will not only reduce noise, shock, and operational stress, but they will also provide a more stable environment for all your industrial applications. For high-price equipment protection, the smart industries have full confidence in Unick Vibration for their vibration-isolating solutions that last long. Seize Your Machines Today with Unick Rubber Air Spring Isolators! Unick Rubber Air Spring Isolators have a proven track record and are thus recommended for upgrading the induction heater protection. Get in Touch with Us Immediately for professional help and to select the most suitable air spring solution for your industrial configuration!

How Unick Spring Pads Extend the Life of Your Heavy Power Press

A heavy power press is one of the most diligent machines present in a manufacturing plant. It exerts enormous force and works on a continuous basis while at the same time coping with the worst-case scenarios in load variations. The major reason for this is that even though the vibrations are subtle, they can still lead to huge mechanical failures. Thus, maintenance costs begin to escalate, and machine life, together with productivity, suffers. Here is where Unick Anti Vibration Spring Pads come into play by providing stability, safety, and power to your press activities. 1. The Science Behind Unick Spring Pads: How They Reduce Vibration and Shock The Unick Spring Pads are made of the best quality elastomers and spring-steel, which are able to absorb, dampen, and neutralize the vibration right where it is produced, through their combination of materials and layering. The product’s development is driven by a straightforward scientific principle: How the Science Works: Consequently, the operators are less tired, the equipment is more stable, and the quality of the production is improved a lot. 2. Key Ways Unick Spring Pads Protect Heavy Power Press Components A power press includes moving, rotating, and impact-producing parts. If there is no proper Heavy Duty Anti Vibration Pads, every component gets damaged leading to misplacement, wear and tear, and ultimately downtime. On the contrary, Unick Spring Pads serve as a barrier that protects the entire machine system. Major Components Protected: Thus, whenever Unick Spring Pads are put into place, the whole machine operates in a synchronized, balanced, and healthier manner. 3. Why Consistent Load Distribution Matters for Longer Machine Life In a heavy power press, uneven load distribution is one of the main causes of premature failure that is most often seen. When a machine vibrates, the load keeps on shifting, which in turn affects the accuracy and internal alignment of the machine. Unick Spring Pads and Anti Vibration Rubber Pads provide the necessary support for load balancing, which contributes to the stability of the machine, even when it is subjected to continuous and heavy operations. Benefits of Consistent Load Distribution: Moreover, the machine is consistently load balanced which prevents the machine from vibrating and consequently, both the operator and the machine are protected. 4. Real Benefits You See: Lower Maintenance, Less Downtime, More Output The Unick Spring Pads are mounted on and the manufacturers are instantly informed of the performance boost. The machine not only runs with less friction but also the financial advantages in the long run are huge. Benefits that are Practical, Real-World: In the end, the power press you have is an asset that lasts a long time rather than an expense that recurs. 5. Trusted Performance by Unick Vibration: Making Power Press Machines Last Longer Unick Vibration is the name that is associated with the manufacturing of top-quality products for vibration isolation in heavy-duty machinery. Their Spring Pads and Anti Vibration Elastomeric Pads have been a reliable device for the industry for many decades. What makes Unick Vibration a trustable partner? So, opting for Unick Vibration means you are getting a reliable, long-lasting, and trouble-free performance for your machines. Conclusion Purchasing a heavy power press is a significant step that requires protecting, stability, and a smooth performance without vibration to be efficient. Unick Spring Pads provide a straightforward yet mighty approach that prolongs machine life, improves output, and cuts down on running costs. In summary, with these cutting-edge vibration-damping pads, manufacturers gain: And ultimately, a power press that lasts longer and operates every day with the same consistency. Do you want to enhance the life, stability, and precision of your heavy power press? Unick Spring Pads from Unick Vibration is your choice, and you will feel the difference today. Get Your Quote | Book Installation | Request a Demo Make your power press stronger, safer, and more productive, beginning today!

Why Your Crochet Machine Needs Unick Spring Pads for Vibration Control

Crochet machines are designed for accuracy, speed, and uniformity. Nevertheless, even the best machines fail to give quality output when the vibrations are beyond the tolerable limits. In addition, high vibration levels can cause thread tension to fluctuate, pattern precision to deteriorate, and overall quality of output to decline. This is precisely the point where Unick Vibration Spring Pads become a revolutionizing factor. These top-quality pads not only support the machine but also safeguard its internal parts and guarantee uninterrupted operation. Hence, those machine operators looking for efficiency, longevity, and quality production are turning to Unick Anti Vibration Spring Pad. How Excessive Vibration Impacts Crochet Machine Performance and Output Quality At first, it may seem that strong vibration is an insignificant problem but soon it will interrupt machine work and lower the consistency of the output. Besides, vibration leads to greater resistance between parts thus weakening the performance. Vibration affects your crochet machine in the following ways: In turn, quality gets worse, downtime is prolonged, and production efficiency declines. Why Unick Vibration Spring Pads Are Engineered for Superior Stability Unick Vibration Spring Pads are a very specialized solution aimed at heavy and high-speed industrial machines, like crochet machines. Furthermore, these pads not only absorb vibration but also do it at the source, which means the vibration can’t reach the floor and the machines’ frames. Why Unick Spring Pads are Best? It follows that Unick Spring Pads will always give production quality a perfect trait, stability! Key Benefits of Installing Spring Pads in High-Speed Crochet Machines Spring pads installation is, after all, not only a technical upgrade but also an investment in the production efficiency and the longevity of the machine. Moreover, Unick Vibration Spring Pads and Anti Vibration Engine Mount are the main reason for the manufacturers’ more fluent outputs and longer life cycles of machines. Primary Advantages are: How Spring Pads Extend Machine Life and Reduce Maintenance Costs One of the major causes of mechanical failure is vibration. Thus, it is necessary to control vibration in order to keep the machine healthy for the long run. Unick Spring Pads Are Of Great Help: As a result, maintenance costs are greatly reduced and the machine runs like new for many years. Choosing the Right Spring Pad Setup for Optimal Crochet Machine Efficiency Selecting the most suitable spring pads is critical for Unick Vibration. Therefore, Unick Vibration offers tailored pad configurations for different machine weights, speeds, and operational requirements. Main Factors to Keep in Mind: Setup Suggested by Unick Vibration: The right setup choice will give the highest output efficiency and the lowest machine vibration, thus prolonging the life of the machine. Conclusion Vibration of high intensity is one of the most detrimental aspects of crochet machines that go unnoticed. Yet, even so, if the technique is chosen, such as Unick Spring Pads and Elastomeric Pads, the owner of the machine can protect the quality of the production, quicken the process, and also assure a durable performance for the long run. Besides all these advantages, the spring pads also give remarkable stability, cut back on maintenance expenses, and assist in keeping the output uniform. Therefore, should you need a dependable and high-capacity crochet machine, the upgrading to Unick Vibration Spring Pads is not just suggested, it is a must. Upgrade Your Crochet Machine Today Are you all set to increase machine stability and solve vibration issues completely? Reach out to Unick Vibration now for Spring Pads that are perfectly designed for the performance of the crochet machine. Get Your Spring Pads Delivered & Installed Enhance performance. Reduce vibration. Improve productivity

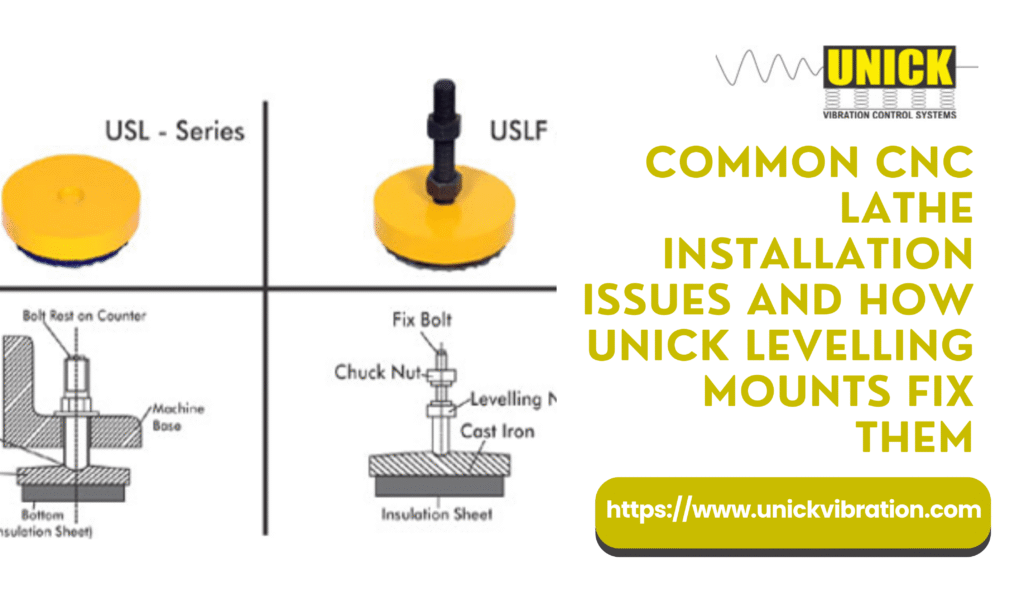

Common CNC Lathe Installation Issues and How Unick Levelling Mounts Fix Them

The installation of a CNC lathe plays a key role in determining its performance. Even the most sophisticated machine can fall short of its potential if problems like misalignment, vibration, or thermal expansion are not dealt with properly. Besides, every millimetre counts in CNC lathes, which are delicate systems. Thus, the operators have to make sure that the installation is stable, accurate, and durable. Unick Levelling Mounts, which are renowned for their engineering excellence and vibration control capacities, are the ones to provide a dependable, well-established solution to these issues. Misalignment During CNC Lathe Installation: How Unick Levelling Mounts Ensure Perfect Accuracy Misalignment is one of the most common installation problems that negatively affects the machining accuracy. In case a CNC lathe is not horizontal or even slightly tilted, the workpiece is not correctly aligned with the cutting tool. Misalignment will also cause spindle runout, tool wear, and inconsistent cuts in the long run. Reasons for Misalignment: How Unick Levelling Mounts Help: Unick Levelling Mounts are designed for easy, perfect alignment of machines with little effort. Moreover, they get rid of the guesswork and human error, which are typical in conventional levelling methods. Main Advantages: Consequently, the machine operators get to benefit from greater accuracy, consistent machining output, and less tool wear. Excessive Machine Vibration and Noise: The Role of Unick Vibration Control Solutions Excessive vibration is one of the main problems during CNC lathe installation with Heavy Duty Anti Vibration Pads, as it deteriorates cutting, surface finish, and the machine’s life. Moreover, vibration contributes to operator weariness and intolerable noise in the workplace. Major Vibration Sources: How Unick Vibration Control Mounts Solve the Issue The Unick Vibration series is undoubtedly the most revered vibration technology that is specifically designed for machines and comes right from Unick. With their mastery, they have developed a line of vibration-control mounts that provide: Thus, the CNC lathes would run smoother, and at the same time, there would be an AWS surface finish and a longer lifespan of the machines. Floor Unevenness Challenges and How Unick Levelling Mounts Provide Stable Support One of the major problems faced in workshops and factories is the existence of uneven floors. The disparity may not be very pronounced to a casual observer, but the CNC machines can feel even a millimetre of the difference. Therefore, ignoring the unevenness of the floor can lead to misalignments and stability issues over a long period. Reasons Why Uneven Floors Are Harmful for CNC Lathes: How Unick Levelling Mounts Fix Uneven Floor Issues The Unick Levelling Mounts are specially built to accommodate irregular or rough floors while still guaranteeing machine stability with Rubber Cork Anti Vibration Pads. Benefits are as follows: To sum up, Unick Mounts provide a perfect ground even when the factory floor isn’t. Thermal Expansion Issues in CNC Lathes and the Fix Offered by Precision Levelling CNC lathes are constantly heating machines. Thermal expansion of machine components, which subtly alters dimensions and alignment, is the long-term consequence of this. Finally, the thermal distortion limits the tolerance and accuracy of machining to a certain extent. The following are the effects of thermal expansion: Precision Levelling mount gives the following advantages: The Unick’s Precision Levelling Mounts are designed in a way that they will reduce the structural stresses created by thermal expansion. Some of their features are: As a consequence, the operators will be able to keep the thermal stability and also ensure the continuous precision machining. Poor Cutting Quality Due to Instability: How Unick Levelling Mounts Restore Machine Performance In a situation where a CNC lathe is not stable, the whole process will be affected, from surface finish to tool life. This will lead to a decrease in productivity and an increase in maintenance costs. Machine instability is a frequent result of poor levelling, ineffective vibration control, or machine feet that shift. What are the Signs of Instability? How Unick Levelling Mounts Contribute to Better Cutting Quality? Unick Levelling Mounts are the ones that make machine rigidity and stability better and in turn make it possible to do high-speed cutting with a stronger foundation. The advantages are: That is why manufacturers can get better precision, shinier finishes, and uninterrupted production. Conclusion Alignment issues such as CNC lathe installation, vibration, uneven floors, thermal expansion, and instability can all lead to a significant decrease in the performance of machines and the quality of products. With Unick Levelling Mounts, these issues are solved in such a way as to guarantee accuracy, stability, and smooth functioning for a long time. In the end, Unick makes sure that the CNC lathes are always at their best performance from the first day and also on every subsequent day. Tomorrow, make your CNC lathe stability better with Unick Levelling Mounts! Unick’s advanced levelling and vibration-control solutions will ensure accuracy, decrease vibration, and lengthen the lifespan of your machine. Get in touch right now for professional help and installation support!

Is Excessive Vibration Killing Your CFC Coiling Machine’s Lifespan? Solved by Unick Spring Pads

CFC coiling machines are the foundation upon which modern manufacturing stands in wire and cable production. But the problem of excessive vibration, though unnoticeable, can shutter silently their efficiency and longevity. Gradually, even the tiniest of vibrational movements pile up to exhaust,. create misalignments, and cause unexpected stoppages. However, the like of Anti Vibration Spring Pad is a good example of a solution that encounters this problem directly, and guarantees your machines to run smoothly, efficiently, and safely. The article here talks about the vibration impact on CFC coiling machines, signs of vibration related damage, and the ways in which Unick Vibration Solutions, especially spring pads, prolong the life of your machine. Understanding the Impact of Excessive Vibration on CFC Coiling Machines Excessive vibration is not just a nuisance to operations, it could lead to significant mechanical problems and financial losses. Vibration is a major factor that undermines the reliability of the entire production facility because it not only affects machine performance but also the operational reliability in the long run. Hence, the facilities that heavily depend on CFC coiling machines should consider investing in vibration reduction methods as a crucial step. Top Signs Your Machine’s Lifespan Is Being Shortened by Vibration Repair costs can run high if not caught early, but identifying the signs of vibration damage is one thing that is preventable. Besides, it keeps your machine working at the highest level of efficiency. So here are a few things to keep an eye on: Thus, immediately acting on the signs of malfunctioning will prevent the machinery from breaking down completely. How Unick Vibration Solutions Protect Your Equipment from Damage Unick Vibration’s Heavy Duty Anti Vibration Pads has a holistic approach towards reducing the negative impact of vibration on industrial machines. Spring pads are a case in point, as they are designed to take in the shocks, make the machine stable, and let it operate without a hitch. In addition, the adoption of Unick solutions leads to increased productivity and reduced chances of expensive repairs, thus guaranteeing a stable and dependable production line. The Role of Spring Pads in Reducing Operational Wear and Tear Spring pads are essential in lessening the electrical and mechanical stress that would otherwise be imposed on the machine due to vibrations. They serve as both vertical and horizontal shocks absorbers by being placed between the machine and its base. Also, the use of spring pads not only prevents but also creates a quiet and safe work environment, which is a plus for both workers and the quality of the product. Long-Term Benefits of Installing Unick Spring Pads on Your CFC Coiling Machine The use of Unick Spring Pads is an investment with palpable long-term benefits. These advantages cover not only the instant vibration control but also the overall cost savings and operational improvements. In the end, the use of Unick Spring Pads is a decision not only related to maintenance but also regarding the planting of a long-lasting and productive industrial operating environment. Conclusion Vibration that is above the normal level can gradually damage your CFC coiling machine, leading to increased maintenance costs, decreased efficiency, and unplanned downtimes. Fortunately, the use of Unick Spring Pads and Levelling Pad Supplier in India is one of the solutions that allow you to protect your machines, ensure the quality of production, and add more life to them. When you are able to notice the signs of vibration, keep going with reliable solutions, and install the springs, you not only secure the production but also get the right conditions for the successful operation of your business in the long run. So, the actions you take today to prevent the high cost of repair tomorrow. Don’t let vibration silently destroy your CFC coiling machine Reach out to Unick Vibration Solutions now and learn how their top-notch spring pads can protect your machines, cut down on maintenance costs, and improve operational efficiency. Invest in longevity. Reduce vibration. Maximize productivity.

Achieve Sub-Micron Precision: The Necessity of Unick Wedge Mounts for Every Modern CNC Machine

In the fierce competition of today’s manufacturing, precision is not just a luxury; it is a must-have. Contemporary CNC (Computer Numerical Control) machines are able to perform very complex designs with an accuracy of less than one micrometer. Nevertheless, precision to that level is not possible only with excellent machines; the components that support the machines also have to be very stable and perform well. This is exactly where Unick Wedge Mounts come in. These mounts, by providing an unparalleled combo of vibration damping, stability, and alignment, ensure that your CNC machines are always at their best, thus producing immaculate results all the time. Understanding Sub-Micron Precision: Why Modern CNC Machines Demand It Sub-micron accuracy means the ability to make very fine measurements, that is, under one micron (1 µm = 0.001 mm). As a result, manufacturers in sectors like aerospace, medical devices, electronics, and automotive are more and more turning to CNC machines to handle these strict demands. Some of the most significant reasons modern CNC machines necessitate sub-micron precision are: In addition to that, CNC machines not receiving the necessary support or damping can be harshly affected by vibrations and misalignments leading to a lack of precision and a reduction in the lifespan of the machine. Therefore, the use of high-quality mounts becomes not only a recommendation but also a requirement. How Unick Wedge Mounts Enhance Stability and Accuracy in CNC Operations Unick Wedge Mounts are specially designed to endure heavy loads and high-speed operation while keeping CNC machines stable and aligned. they effectively reduce movement that can disrupt machining accuracy. Key Features Include: Also, the wedge-like shape of the weights goes evenly from one side to the other, thus ensuring the operation of the whole machine in harmony with Heavy Duty Anti Vibration Pads. In consequence, the process of machining develops to be smoother, more dependable, and capable of achieving sub-micron precision consistently. Reducing Vibrations with Unick Vibration for Superior Machining Results Vibrations are the quiet destroyers of CNC precision. Even the slightest movements can result in defects, wrong cuts, and rough surfaces. The Unick Vibration technology combined with the Wedge Mounts has the ability to greatly reduce these problems. How it works: As a result, manufacturers gain the benefits of excellent surface quality, very tight tolerances, and minimum machine components. Key Benefits of Wedge Mounts: Longevity, Repeatability, and Flawless Cuts Unick Wedge Mounts are not merely supports; they are performance boosters. Some of the advantages that come with their use are positively listed below: Besides, premium quality wedge mounts investment will save you money, and your production will be efficient and up to the whole operation quality. Choosing the Right Wedge Mount: Factors Every CNC Operator Must Consider It is very important to choose the right wedge mount. The CNC operators have to take into account a number of parameters in order to get the utmost advantage from Unick Wedge Mounts: Finally, the collaboration with the Unick specialists and the execution of a thorough load and vibration analysis guarantee that the selected wedge mount will give the best performance. Conclusion To sum up, modern CNC machines cannot reach sub-micron precision without proper support and vibration control. Unick Wedge Mounts guarantee the stability, damping, and precision that are needed to take machine performance to the highest level. In addition, it prolongs the life of your CNC equipment, reduces maintenance costs, and assures continuous perfect output. For the manufacturers playing to the top of production standard and keeping the competitive edge, Unick Wedge Mounts are not just an accessory; they are a must. Don’t compromise on precision Transform your CNC operations right now with Unick Wedge Mounts and feel the stability and precision that are impossible to match. Get sub-micron precision. Increase productivity. Ensure flawless results, only with Unick Wedge Mounts.

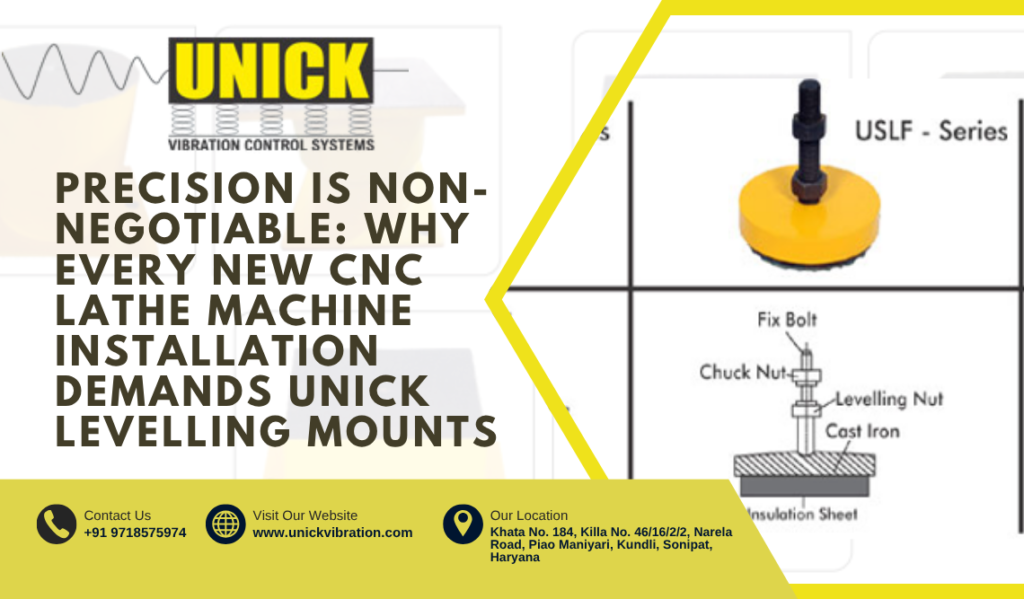

Precision is Non-Negotiable: Why Every New CNC Lathe Machine Installation Demands Unick Levelling Mounts

Precision is the only way in today’s high-tech manufacturing world. CNC lathe machines are the main actors in modern production, manufacturing complex parts with incredible accuracy. Yet, to reach this accuracy threshold, besides the machine, the area underneath it is important, too. This is the part where Unick Levelling Mounts come in, providing stability, cutting down on vibrations, and improving the performance of the machine from the very first day. The Role of Levelling Mounts in Achieving CNC Lathe Precision Levelling mounts, or machine mounts as they are sometimes called, are very small but powerful parts that have a direct effect on CNC performance. In simple terms, these mounts serve as the connection between the machine and the floor and keep the lathe perfectly aligned. On top of that, correct levelling minimizes the chance of errors in the course of high-speed machining, which in turn leads to greater accuracy for every cut, bore, or thread. Unick Vibration Solutions: Setting the Standard for Machine Stability Unick has been recognized as a major player in the vibration solutions industry for the sake of industrial machinery. The company not only makes first-class levelling mounts but also delivers solutions that are specifically designed for CNC applications. Thus, applying Unick levelling mounts is an advance in the direction of the machines being durable. Furthermore, Heavy Duty Anti Vibration Pads manufacturers would be very happy as they would have less downtime, and fewer quality problems which ultimately would lead to increased productivity. Installation Matters: How Improper Levelling Compromises CNC Output A sophisticated CNC lathe cannot be at its best if not levelled right. Many errors come up because of the neglect of installation steps. So really, a misaligned CNC lathe can make one lose a lot of money not only by scrapped parts but also through maintenance and support costs. It is therefore a must to use professional-grade levelling mounts for proper installations. Key Benefits of Using Unick Levelling Mounts for CNC Machines Unick levelling mounts give clear and instant benefits, thus they are the number one option for the up-to-date manufacturing plants. Besides, operators and engineers are now more assured that their CNC machine is underpinned by world-class vibration solutions, thanks to these mounts. Ensuring Long-Term Performance with Proper CNC Machine Alignment The ability to maintain high precision and quality in operations of a CNC lathe remains largely dependent on its initial alignment and routine maintenance done throughout its life cycle. Levelling mounts are, therefore, of invaluable assistance in this matter. Furthermore, occasional inspection and fine-tuning of Unick leveling mounts keep the machine in prime condition, thus case of proactive maintenance together with quality mounts yielding long term savings and reliability. Conclusion To sum up, it all comes down to the foundation when it comes to precision in CNC lathe machining. Unick Levelling Mounts are the backbone that provides stability, vibration control, and longevity hence making them a vital investment for any manufacturing place. By focusing on proper installation and alignment, the manufacturers not only assure that the output quality is high but also keep the machine in good condition for a long time. Integrating Unick levelling mounts into the CNC operations is a strategic move for manufacturers who want to produce consistently and with high precision. Take Control of your CNC lathe’s Precision Today Unick Levelling Mounts is your best bet for stability that never changes, downtime that is insignificantly low, and quality of the output that is top-notch. Unick Vibration Solutions should be contacted right away to set up your installation and raise your standards of manufacturing. +91 9718575974 | https://unickvibration.com.

Precision is Power: How Unick Wedge Mounts Ensure Flawless CNC Engraving Results Every Time

CNC engraving has brought a change in the way manufacturing is done nowadays, as it has made the process of the highest accuracy and the greatest speed as well. However, even the best of the CNC machines need proper stability and support to work of consistent quality. Unick Wedge Mounts are the solution for that machine stability and support. Not only do they look good, but they also sculp and carves, they are that good. This article is dedicated to showing how Unick Wedge Mounts bring CNC engraving up, how they enhance productivity and how they make machinery less prone to wear and tear. Besides, it will be discussed why precise mounting means error-free results. Engineered Stability: The Core Advantage of Unick Wedge Mounts in CNC Engraving In CNC operations, stability is the name of the game. The time when engravings were ruined by even the tiniest movements or vibrations is long gone because Unick Wedge Mounts are man-made devices specifically designed to prevent these problems. Key Benefits of Engineered Stability: Besides the above-mentioned advantages, Unick’s engineering gives the mounts the ability to withstand heavy loads which m. Their frequency of use in demanding manufacturing environments comes as a logical consequence. Achieving Micron-Level Accuracy Through Superior Mounting Technology Precision represents not only speed but also micron-level accuracy allowing to manufacture very intricate engravings, for instance. Unick Wedge Mounts succeed in this by utilizing the latest design techniques, thus offering it. How Unick Guarantees Precision: Therefore, the Heavy Duty Anti Vibration Pads manufacturers can boldly make complicated designs, intricate logos, and fine details that would not be possible with standard mounting solutions. How Unick Vibration Solutions Enhance Performance and Minimize Machine Disturbances One of the biggest problems in CNC engraving is vibrations which often result in rough edges, unintentional tool wear, and production inefficiency. Unick Vibration Solutions incorporated in their wedge mounts are very effective in eliminating these problems. Benefits of Vibration Reduction: Also, by dealing with the vibrations at the outset, Unick allows the machines to run at their highest speeds without losing the quality of the cutting. This results in the same amount of work done by the company being less and thus paves the way to higher profits and lower costs. Boosting Productivity and Tool Life with Precision Mounting Systems Productivity is directly linked to precision and machine life span taking CNC tools as an example. Unick Wedge Mounts are a two-in-one solution as they are able to not just improve engraving accuracy but are also one of the main factors contributing to the overall efficiency and longevity of CNC tools. Key Productivity Advantages: Furthermore, the stability also employs the operators’ attention to intricate tasks without being monitored all the time, hence, the workflow is made to be smooth and efficient. Why Every CNC Engraver Trusts Unick Wedge Mounts for Consistent, Flawless Results Trust is built when the results are always excellent. Unick Wedge Mounts are the ones that all the worldwide CNC engravers turn to because they produce outcomes that are reliable, repeatable and every time again. Reasons for the Trust of the Industry: Thus, it is not only a decision to buy Unick Wedge Mounts but also a strategic decision in any CNC engraving operation where precision, efficiency and reliability are sought. Conclusion In the end, precision is the giant in the world of CNC engraving. Unick Wedge Mounts represent the principles of this with their ability to provide stability, reduction of vibrations, and ultimately obtaining micron-level accuracy. Hence, the operators enjoy smooth operations, longer tool life, and consistent output of high quality. No matter if you are engaged in delicate designs or producing large quantities, with Unick Wedge Mounts quality performance of your CNC machine is guaranteed every time. Reach a new level in your CNC engraving today. Precision operations can benefit a lot from using Unick Wedge Mounts. CNC Precision Boost is Available Now! Get in touch with Unick Vibration Solutions to give your CNC machines the wedge mounts that ensure perfect results. To get more details, call +91 9718575974 or go to https://unickvibration.com.

Stop the Shake: 5 Signs Your Buffing Machine Needs Immediate Anti-Vibration Spring Pads

Precision and efficiency turn out to be the defining traits in the industrial polishing and buffing world. Nonetheless, the most sophisticated buffing machines can still be subjected to constant vibrations, resulting in subpar quality of the product and endangering the safety of the operators. In addition to this, neglecting the issue can lead to expensive maintenance and shorter lifespan of the machine. Fortunately, among the solutions, Unick Vibration spring pads have emerged that help keep your machines in a stabilized condition thereby allowing consistent output and smooth operations. In this piece, we will discuss the 5 major indicators that signal the urgency of equipping your buffing machine with anti-vibration spring pads. Unstable Polishing Results? Unick Vibration Pads Have the Perfect Fix The tiniest shake or wobble will simply ruin the surface quality if you are looking to get a flawless finish. First, take a look at the results of your polishing jobs: if there are uneven textures, swirl marks, or inconsistent shine, then probably your machine is vibrating too much. Therefore, it is guaranteed that when installing Unick Anti-Vibration Spring Pads, the machine will be stable during operation and the operators will be able to make consistent and professional results every time. Excessive Noise and Floor Vibrations: A Warning Your Machine Can’t Ignore Moreover, another clear indication of excessive machine vibration is the transfer of loud noise and vibration to the surrounding area. Such machines that vibrate a lot usually introduce a low-frequency hum or rattling sound, which can distract and pose a danger at the same time. As a result, the pads meant for preventing vibrations are important not just for the machine but also the surrounding environment. These pads take shock in and reduce noise thus making the workplace safer and more comfortable. Increased Operator Fatigue: When Shakes Turn Dangerous Moreover, excessive machine vibration affects the operator as much as it does the machine. Using a vibrating buffing machine over the long haul can leave the operative prone to physical exhaustion and strain. Therefore, controlling machine vibration not only extends the life of machinery but also keeps workers healthy. The use of Unick Vibration Pads decreases the strain as the operator is always comfortable and hence, able to work efficiently. Loose Bolts and Misalignment: The Hidden Damage of Ignoring Vibrations Also, a subtle form of vibrations can lead to structural damage that is hard to detect. Constant shaking will not be noticed by the operator but will result in loosening of bolts and misalignment of critical components. Thus, getting anti-vibration spring pads is a safety measure. By keeping the machine steady, you not only safeguard the internal parts but also the performance over time. Shortened Machine Life and Higher Maintenance Costs: The Final Red Flag In the end, an unchecked vibration condition presents the most severe consequence of accelerated wear and tear of your buffing machine. That is why your equipment might fail sooner than expected, and the maintenance costs could be enormous. In brief, the anti-vibration pads are a minor investment that brings significant returns by extending the lifespan of the machine and cutting down the ongoing maintenance costs. Conclusion To sum up, the continuous vibrations in buffing machine are not only a minor problem, but also a major warning that must not be ignored. From inconsistent polishing results and loud noise to fatigue of operator, loose parts, and wear out faster, the signs are so obvious. Fortunately, the Heavy Duty Anti Vibration Pads offer the simplest and most effective solution and that is stability, safety and precision. In the end, the correct anti-vibration solution will not only safeguard your investment but also improve the quality of work and make the workspace safer and more efficient. Take Action Now! Do not allow vibrations to affect either your results or the safety of your workers. At first, you should get in touch with Unick Vibration to get your buffing machines upgraded with anti-vibration spring pads of the best quality and thereby, experience the performance of your machines that is extraordinarily smooth, stable, and accurate.